Figure 1: Servo drive and servo motor manufactured by TECO.

1. TECO Servo Product Series

TECO Servo DriveTECO Servo Drive: series JSDAP/JSDEP

TECO Servo MotorTECO Servo Motor: series JSMA

Figure 2: TECO has servo drive and servo motor.

2. Features of TECO Servo Products

Model is complete. Type-JSDA is used with 8192 PPR encoder. The servo motor JDDE is complete with 50W~15KW models and used with 2500PPR encoder.

Functional diversity. It has a function of switching torque, speed, position, point-to-point and mixed mode, and can be matched with a variety of control systems.

Main loop/control loop has power separation. This has good protection coordination and easy to do spot inspection.

Built in 16 segments position setting. It’s free to plan point-to-point positioning control.

Perfect protection mechanism: Multiple abnormal alarm

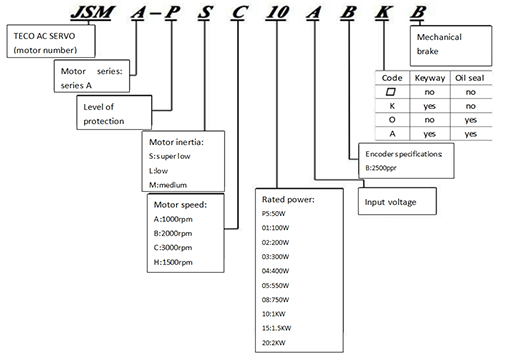

3. Naming Rules of TECO Servo Model

Figure 3: Naming rules of TECO servo motor.

4. Environment Requirements of TECO Servo

Ambient temperature: 0~+40°C ; ambient humidity: below 90% HR (No frosting condition)

Storage temperature: -20~+60°C ; storage humidity: below 90% HR (No frosting condition)

Vibration: less than 2.5G

A well-ventilated place with little moisture and dust

Non-corrosive, ignition gas, oil and gas, cutting powder, cutting fluid, iron powder and other environment

No moisture and direct sunlight

5. Application Cases of TECO Servo

5.1 JSDA Servo Drive in Tensile Machine

Tensile machine is mainly used for tensile compression, bending test of plastic sheet, pipe, profile, plastic film and rubber, wire and cable, waterproof coil, metal wire and other materials. It is ideal testing equipment in the industry and mining, commodity inspection and arbitration, scientific research units, colleges and universities, engineering quality supervision station and other departments.

Figure 4: Tensile machine with TECO servo drive.

The tensile machine is equipped with JSMA-LC08AH (750W) motor and JSDA20A drive, and the motor is equipped with a 1:30 planetary reducer. The drive works in the position mode. The electronic gear ratio is 2500 pulses a week, and the weekly pulse output is 2000. The test speed of the equipment is 0.5 mm/min - 500 mm/min.

The device controller are generally manufacturer's own MCU, and pulling force driving part adopts AC servo motor, deceleration machine with synchronous belt driving lever up and down.

The motor is required to operate at a very low speed during normal operation. When the work is completed, the motor needs to return to the starting point at a high speed of 4500 RPM. Our motor can run up to 1.5 times the rated speed, so we can overcome this bottleneck.

the actual displacement of pull lever is converted from the number of pulses output by the servo encoder. Upper count uses single pulse count. because the servo motor does dynamic adjustment and always has small oscillation phenomenon, this will cause counting inaccurat. The lower the speed, the more obvious the inaccuracy. Standard servo is difficult to ensure the accuracy of the count. After knowing the actual needs of customers, you should adjust pulse error to 3. When the servo motor oscillates within a certain range and there is no pulse output. The output pulse is only when the allowable error value is exceeded. So at the beginning of the run, there exists three pulse errors, but does not affect the precision of the count and the three pulse do not accumulation. You can set parameters as follows:

CN001 = 2, CN002 = 0010, CN005 = 2000, CN030 = 212, PN301 = 1, PN302 =4, PN313 = 0, HN515 = 102.

5.2 TECO Servo Drive in CNC Fibre Planting Machine

With the wide application of automatic control technology in toothbrush manufacturing industry, the efficiency of toothbrush production has been significantly improved, which plays a positive role in the revolutionary technological innovation of toothbrush manufacturing industry.

Due to its outstanding cost-effective advantages and mature application experience, TECO servo system has been fully recognized in the toothbrush machine manufacturing enterprises in South China.

The electrical configuration mode of PLC + HMI + TECO TSTA series servo motor is becoming more and more adopted in the market.

Figure 5: TECO servo in CNC fibre-planting machine.

5.2.1 Work Principle of Fibre Planting Machine

There are 4 sets of TECO TSTA series servo drives used in the toothbrush fibre planting machine.

Among them, 1 set of 400W servo control system controls the clamps with toothbrush handle to make 90 degree positioning (internal position control), and 2 sets of 750W servo drive the platform fixing clamps to make X and Y axis movement (PLC sends pulse for external position control), requiring high speed response and accurate positioning.

The 4th set of 750W servo control switches different colors of bristles (internal position control). There is also a frequency converter to drive an ordinary motor through the CAM to do fibre-planting action.

Action process: the clamp clamps the handle of the toothbrush from the direction of Y axis → the clamp is positioned 90 degrees to the direction of Z axis → the platform drives the clamp to move along X and Y axis so that the bristles can be hit into the pores of the toothbrush head → hair planting is completed, the clamp rotates 90 degrees downward → the clamp loosens and the processing of a toothbrush is completed.

The new CNC high-speed fibre-planting machine adopting the TECO servo positions precisely, and its positioning accuracy can be 0.05mm/100mm. The response is also fast, and its speed can reach up to 750 holes/min.

5.3 TECO Servo Drive in Engrave Milling Machine

Engrave-milling machine is a CNC machine tool. It is a kind of high efficiency and precision CNC milling machine. Engrave-milling machine can be understood having both fine engraving and milling functions. Compared with engraving machine, it increases the power of spindle and servo motor, bed bearing force, while maintaining the high speed of the spindle, and more importantly, the accuracy is very high.

Compared with CNC milling machine, engrave-milling machine is more suitable for small mold processing small tool , and more inclined to high speed. It is generally believed that engrave-milling machine is a CNC milling machine which uses small cutting tool, high power and high speed spindle motor .

Figure 6: TECO servo in engrave-milling machine.

5.3.1 Hardware Configuration

|

Opitical Machine |

600*500 (3axis-X,Y,Z) |

|

Tool Magazine |

BT40 turntable style (8 tools) |

|

Principal Axis |

Motorized spindle (-12000RPM) |

|

CNC |

ME3 + 32I/0 |

|

Table Feed (X axis) |

TECO JSDEP (750W/3000RPM) |

|

Table Feed (Y axis) |

TECO JSDEP (750W/3000RPM) |

|

Spindle (Z axis) |

TECO JSDEP (750W/3000RPM) |

|

Spindle Frequency Converter |

TECO frequency converter N310 |

Table 1: Hardware configuration of engrave milling machine.

5.3.2 Advantages of TECO Servo for Engrave Milling Machine

TECO servo JSDEP is an economical servo of this company with power range of 100W-2KW. At the same time, it has the feature of a high performance-cost ratio and excellent performance. As a general-use servo, it can be applied to many industrial machinery, and it is convenient to control and simple to operate.

In the engrave-milling machine, to achieve high speed and high precision, in addition to the requirements of the system performance is good enough, the requirements of the servo is also very high. Due to the need to do curved surface processing, it is not only requires accurate servo positioning, but also requires high dynamic response. Through the debugging, it is verified that the TECO servo in the engrave-milling machine is no problem. In order to make the best use of servo, you should pay attention to the following aspects.

In order to ensure the accuracy of the whole machine, the rigidity of the optical machine is required to be better. In this case, the marble machine is used, and the rigidity of the machine is good enough;

Adjust the appropriate gain. It can not only achieve the accuracy requirements, but also avoid vibration. TECO servo has 10 levels of rigidity, and is suitable for different equipment requirements. In this case, rigidity level 8 was chosen;

In order to achieve high rigidity, sometimes you need to do the detection of the vibration of the machine tool. Through the correct setting of servo parameters, you can effectively avoid the vibration point.

5.3.3. Using Tips

In the initial test run, CNC code must calibrate machine zero and program zero. In this way, the correct offset value of each axial direction can be got to ensure the correctness of the machining work piece.

Debugging of hat knife library. It is very easy to bump the knife. So, you should ensure the correctness of the program and do the corresponding protection;

The electric spindle is strictly prohibited to operate without a knife. Remember to ensure the correctness of the program and do the corresponding protection.

6. How to Solve Low Speed Vibration of TECO Servo Motor

TECO servo JSDA-50A3 / JSMA-MB20ABK01 is an old model used in automatic one-step hollow molding blowing machine. The injection and pull blowing machine and runs smoothly and has excellent performance in injection-stretch-blowing molding machine.

But the new TECO servo JSDAP-50A3 / JSMA-MB20ABK01 runs extreme vibratorily in the injection-stretch-blowing molding machine at low speed. The lower the speed is, the vibration is more strong. Why is that?

The reason is that the automatic gain adjustment parameter CN25 of the new TECO servo JSDAP-50A3 / JSMA-MB20ABK01 is only 10 when it is delivered from the factory, so you need to adjust it to 40. And the automatic gain adjustment parameter CN25 can even be adjusted to 50.

In this way, the problem of low speed vibration of the injection-stretch-blowing molding machine can be solved.

Related Info

TECO Servo JSDEP Works for Food Placement Machine

Basics of Servo Motor You Should Know

Where is Servo Motor and Servo Drive Used?

Application of Servo System in Textile Machinery