Why is the refrigeration compressor always overheating protection?

Compressor overheating protection means to protect the compressor motor from being burned. When the motor temperature or the compressor's own temperature exceeds a certain value, some built-in or external protection devices are used to disconnect the compressor's working power supply to achieve protection The role of the compressor. The refrigeration compressor sucks low-temperature and low-pressure gaseous refrigerant from the system and directly enters the shell cavity of the compressor. The sucked refrigerant first cools the motor and then compresses it. Therefore, the degree of superheat of the suction refrigerant vapor is an important reason for whether the compressor is overheated. Today we will analyze the problem and hope it will help you.

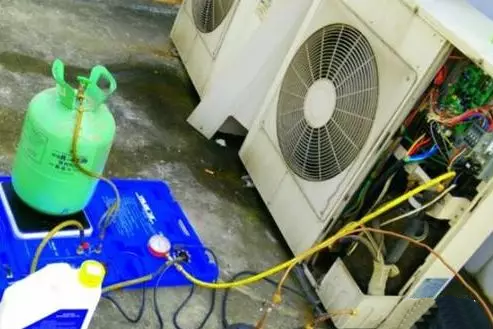

1. Lack of refrigerant:

Lack of refrigerant will reduce the amount of refrigerant provided to the evaporator, resulting in high evaporating temperature and high temperature of refrigerant vapor sucked in by the compressor, that is, high superheat, which will cause the compressor motor coil to overheat and cause overheat protection.

In the hot summer, the ambient temperature is too high. When the lack of refrigerant in the system is not too much, it is difficult to judge by the current of the compressor and the pressure measured by the system. On the contrary, it is easy to overfill. At this time, the temperature of the compressor discharge pipe can be measured. When the temperature is normal, it is about 20℃ higher than the saturation temperature corresponding to the discharge pressure at this time. If it is lower than this value, it means that there is too much refrigerant. If it is higher than this value, it means that the refrigerant insufficient.

The temperature of the suction pipe of the compressor can also be measured. When the temperature is normal, it is about 7°C higher than the saturation temperature corresponding to the suction pressure at this time. If it is too high, it indicates that the suction is overheated and the refrigerant is insufficient. (Refer to the table below) For example, if the actual high pressure you measured is 1.83MPa and the exhaust temperature is 85℃, then the condensing temperature in the table below is 50℃, 85>50+20. If the system heat dissipation is good, it means the system is lacking. Refrigerant.

R22 refrigerant system temperature and pressure comparison table

2. Many refrigerants:

Everyone knows that the evaporation pressure is high, and the evaporation temperature is also high. Because the overall pressure is high, the high pressure is naturally high, and the burden on the press is heavier. The weather is very hot, the heat dissipation is not easy, and the current is large. You say it does not heat and maintain energy OK. The general performance is: the wind blown by the fan of the outdoor unit is hotter than others, and the condensation of the indoor unit is quite even, but it seems that no one sees cold like that. The thin tube valve is not cold, and the thick tube valve is cold. Problem, at noon, I love heat protection, the voltage is no problem, the filter and the external heat are very clean. Some people just add fluorine according to the rated current and what they call current, and the result is more fluorine. Previously, our Refrigeration Encyclopedia public account has also analyzed, according to the shortcomings of current adding fluorine, this is one of the manifestations.

3. Dirty evaporator/dirty condenser

If the evaporator does not dissipate heat well, it can be equivalent to the case where the internal fan is not rotating. We all know that the refrigerant in the evaporator has poor evaporation effect at this time, so the compressor should suck in a gas-liquid mixed refrigerant. In this case, the compressor return air should be frosted, so if the evaporator heat dissipation is not good, it cannot be used as the reason for the compressor overheating. However, when the heat dissipation of the evaporator is not good, the amount of refrigerant sucked by the compressor will be insufficient, that is, the refrigerant circulation is not enough, this situation is completely possible to cause the compressor to overheat protection. Therefore, it is recommended to clean not only the condenser but also the evaporator when repairing the compressor overheating protection failure.

As for the dirty condenser, it is easy to understand here. The condenser does not dissipate heat well and cannot take away heat. The pressure will naturally be high, and the pressure will be high and the current will naturally be high. Over time, thermal protection will be produced.

Poor heat dissipation case

Workers go to repair a thermal protection. The outdoor unit is installed in the air-conditioning niche of a high-rise apartment. There are shutters. The windows are angled at 45 degrees. The area of the niche is small. There is not much space for the outdoor unit. The wind blown out by the leaves is in a figure eight shape. The wind meets a considerable part of the wind resistance, and the page of the shutters is downward; the wind resistance is relatively large, and the outer edge of the figure eight figure basically seals the wind in, and the wind out The inner edge is sucked back by the suction of the fan, so that the fan sucks in not natural wind, but heated wind. After explaining and negotiating with the user, remove the blinds, and then direct the condensate from the indoor unit to the outside for heat. The test machine is more than an hour without thermal protection.

Fourth, the capillary or the system is blocked

The micro-clogging of the capillary group is similar to that of the capillary tube. The throttling is too high, the high pressure will be higher and the low pressure will be lower. The wind blown by the external fan is very hot, which proves that the high pressure is too high. Incomplete evaporator condensation is the specific manifestation of low evaporation pressure. The general performance is: poor refrigeration, incomplete condensation of the evaporator, hot wind blown by the external heat, the original machine can barely work, and some refrigerant is added, and the press completely does not work. When the refrigerant is as hot as others, the condensation of the evaporator will be worse, and the thick pipe valve will hardly be cold.

Five, low voltage

Practice has proved that when the power supply voltage drops below 190V, the system pressure will not rise at high pressure and will not come at low pressure. This is equivalent to the blow-by of the compressor, which causes the specific volume of the refrigerant gas sucked by the compressor to increase, causing the compressor return gas to increase in superheat and leading to thermal protection.

Thermal protection case caused by low voltage

There used to be many machines in a certain area that were thermally protected. When I went to see the site, the machine did not work. The voltage seemed to be similar to 210V, but when other appliances were turned on, the voltage dropped immediately. The voltage was lower than 190V, and the air conditioner could not If it is normal, the press cannot be started, and the press is very damaged.

Sixth, the compressor itself

Four-way valve blows air: The compressor is cooled by low-temperature return air. If the four-way valve blows air, the compressor sucks in not cold air but hot air. Not only will the compressor not be cooled, it will also " Add fuel to the fire, but it’s strange if it’s not hot! The compressor is air-stranded, the refrigeration is not good, and the high pressure will not be able to protect it!

Lack of oil: The compressor is indeed thermally protected if it is out of oil. Lack of oil will lead to poor lubrication of mechanical parts. We also did a detailed analysis of this problem before the public.

Capacitors: It is not uncommon for bad capacitors to cause thermal protection of the press. Sometimes the capacitors bought on the market are not reliable. This kind of thing is not uncommon.