Figure 1: Different types of fans.

Quietness and longevity have always been two very important performance parameters in the PC heat dissipation field,

and the fan can be said to be the biggest source of noise inside

the entire computer case. Many people think that parameters such as fan blade design, speed and air volume are the

biggest factors affecting fan noise.

In fact, the computer fan bearing type is what we should value most. It can be said that the bearing is the soul of

the fan, because different types of bearings will not only affect the service life of a fan, but also the noise of

the entire fan.

Therefore, if we want to choose a fan that suits our actual needs, we must first start with the type of bearing. In

order to let more players have a deeper understanding of the seemingly inconspicuous fan bearings, this article will

mainly focus on different fan bearing types, from parameter performance to analysis of advantages and disadvantages.

1. Common Sleeve Bearing and Hydraulic Bearings

1.1 Sleeve Bearing

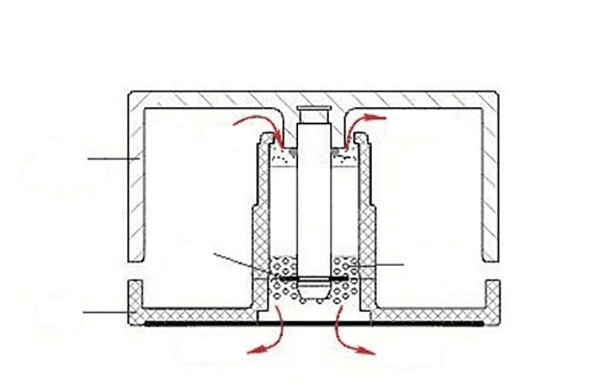

Figure 2: Structural diagram of sleeve bearing.

Sleeve bearings are oil bearings that use sliding friction, and use lubricating oil as a lubricant and drag reducer.

Although the noise is low and the manufacturing cost is low, the wear is serious and the service life is far behind

that of ball bearings.

And after a long time of use, due to the oil seal, the lubricating oil will gradually volatilize, and the dust will

also enter the bearing, which will cause problems such as slower fan speed and increased noise.

When the lubricating oil inside the bearing is insufficient, there will be an obvious "eccentric" state, which will

cause the fan blades to stop in severe cases, resulting in poor heat dissipation, so ordinary oil-impregnated

bearings are not suitable for high-speed or larger size (9cm or more) fan use. Usually, the service life of oil

bearing fan products is 5000-8000 hours.

1.2 Hydraulic Bearing

Hydraulic bearings are improved on the basis of oil bearings. Hydraulic bearings have a larger oil storage space

than oil bearings, and have a unique loop-back oil supply circuit. The improved hydraulic bearing has a longer

service life than oil-impregnated bearings, and also has the advantage of low operating noise.

The average life of hydraulic bearings is 40,000 hours and was originally pioneered by AVC. As more and more radiator manufacturers use hydraulic

bearing technology, fans of this type of bearing have a higher proportion in the current radiator market. Low price

and low noise make it the first choice of many ordinary PC DIYers.

2. Longer Life Ball Bearings

The ball bearing changes the friction mode of the bearing, adopting rolling friction. This mode more effectively reduces the friction phenomenon between the bearing surfaces, effectively improves the service life of the fan bearing, and thus prolongs the service life of the radiator. The disadvantage is that the process is more complicated, which leads to increased cost and higher working noise.

2.1 Single Ball Bearing

Figure 3: Single ball bearing structure diagram.

The single ball bearing (1 ball+1 sleeve bearing) is an improvement on the traditional oil-impregnated bearing. It

adopts the mixed form of sliding friction and rolling friction. In fact, it is to use a ball bearing with an

oil-impregnated bearing to reduce the cost of double-ball bearings.

Between its rotor and stator, it is lubricated with balls and equipped with lubricating oil. It overcomes the

problems of short service life and unstable operation of oil-impregnated bearings.

The single ball bearing absorbs the advantages of the oil-impregnated bearing and the double ball bearing, and

increases the service life of the bearing to 40,000 hours. The disadvantage is that after the ball is added, the

running noise increases, but it is still smaller than that of the double ball bearing.

2.2 Double Ball Bearing (2 Ball Bearing)

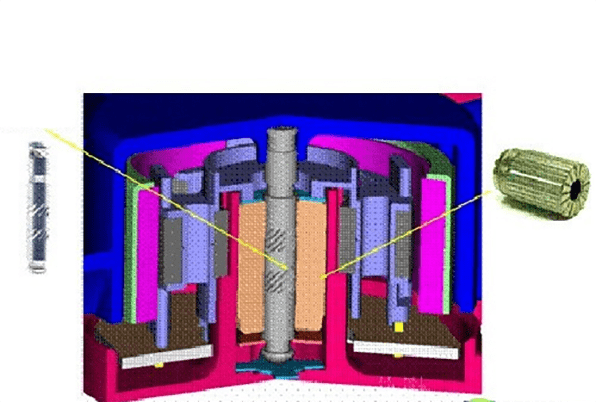

Figure 4: Structural diagram of double ball bearing.

Double ball bearing is a relatively high-grade bearing, adopting the form of rolling friction. It uses two ball

bearings and there are several tiny steel balls in the bearing around the axis. When the fan or the axis rotates,

the steel balls will rotate accordingly. Because they are all balls, the friction force is small, and there is no

oil leakage problem.

The advantage of the double ball bearing is that it has a long service life, about 50,000-100,000 hours. With good

anti-aging performance, it is suitable for fans with high speed. The "violent fan" that some players are more keen

on uses double ball bearings.

3. Rifle and Hypro Bearings

Although the ball bearing has a longer service life, the loud noise is still a headache for most players at present, so some manufacturers have improved the original oil-impregnated bearings to realize the increased service life and low noise. Rifle bearings and hypro bearings were born from this.

3.1 Rifle Bearing

Figure 5: Rifle bearing structure diagram.

As an improvement of traditional oil-impregnated bearings, rifle bearings are made of high-oil-containing hollow

bearings made of wear-resistant materials, which reduces the friction between the bearing and the shaft core. Rifle

bearings also have shaft cores with reverse spiral grooves and oil retaining grooves. When the fan is running, the

oil will form a reverse flow, so as to avoid the loss of oil, thus improving the bearing life.

By adopting the above structure and parts, rifle bearing fan greatly improves the oil lubrication capacity, and

reduces the noise.

3.2 Hypro Bearing

Figure 6: Hypro bearing diagram.

The hypro bearing can be regarded as an improved version of the rifle bearing. The fluid pressure can be effectively

increased by using the "V"-shaped (herringbone) groove design. Different from the circulating circuit oil supply

system of rifle bearing, the hypro bearing always limits the lubricating oil inside the shaft core.

This bearing uses the hydrodynamic properties of fine grooves to fill the gap between the shaft and the bearing with

lubricant. In order to keep the lubricant, the surface of the bearing is engraved with "V"-shaped grooves. When the

spindle rotates, the fluid pressure rises, which can also concentrate the lubricant inside the bearing, making it

less likely to leak.

In addition, the use of such a bearing design not only further improves the service life of the fan, but also

further enhances the noise reduction effect of the fan during operation, making the fan quieter.

4. Nano Ceramic Bearing

Figure 7: Nano ceramic bearings.

Nano Ceramic Bearing (NCB) is still an oil bearing in essence, which was first introduced by Foxconn in its

products. The traditional oil-bearing fan has serious wear and tear during use, and its reliability is low when it

is used for a long time. NCBs effectively overcome this problem.

Ceramic bearing technology uses special polymer materials and makes it fully integrate with special additives. The

core of NCBs is fully made of special zirconium dioxide material, which is made by die and sintering process. The

crystal particles have been reduced from 60um in the past to 0.3um, featuring firmness, smoothness and wear

resistance.

NCBs have strong high temperature resistance, which greatly prolongs the service life of the fan. The properties of

this type of bearings are similar to ceramics, and the more they are worn, the smoother they are. According to

tests, the average service life of fans using NCBs is more than 150,000 hours. This technology is not really

nanotechnology, and the materials used are not really nanoscale materials, but the word nano is used to catch

people's eyes.

Compared with ball bearing fans, the noise of nano ceramic bearing fans has been well controlled, and the noise

generated is 2-3dB lower than that of double ball bearings. The assembly process of the nano ceramic bearing fan is

also much simpler than that of the ball bearing fan, which improves the quality and reduces the cost virtually.

Due to the small size of the nano ceramic bearing, the winding of the motor can be lengthened in the design of the

fan, thereby increasing the motor power and the fan speed. Compared with the ball bearing fan, its central area is

smaller, which effectively increases the space area of the blades and increases the air flow.

5. Silent Magnetic Bearing

Figure 8: Magnetic bearing structure diagram.

The magnetic bearing uses magnetic force to suspend the rotor in the air, so that there is no mechanical contact

between the rotor and the stator.

Compared with traditional ball bearings and oil-impregnated bearings, magnetic bearings have no mechanical contact,

and the rotor can run at high speeds. It has the advantages of small mechanical wear, low energy consumption, low

noise, long life, no need for lubrication, and no oil pollution, especially suitable for high-speed, vacuum,

ultra-clean and other special environments.

In fact, magnetic levitation is only an auxiliary function, not an independent bearing form. Its specific

application must cooperate with other bearing forms, such as magnetic levitation + ball bearing, magnetic levitation

+ oil bearing, magnetic levitation + VAPO bearing, etc.

6. Barometric Ball Bearing

Figure 9: Barometric ball bearing structure diagram.

Fans using this bearing technology have a longer service life and lower noise than traditional bearings.

From a structural point of view, the barometric ball bearing is similar to the magnetic bearing, except that the

magnet that fixes the metal ball is placed at the bottom of the fan. And a certain air pressure is formed on the

outer frame of the fan shaft to ensure the stability of the shaft rotation.

In terms of service life, barometric ball bearings have an average trouble-free running time of up to 100,000 hours,

which is obviously superior to ball bearing fans. However, since there are not many manufacturers using this kind of

bearings at present, the price is relatively expensive.

7. Each Bearing Type Has Advantages and Disadvantages

Finally, let us look at some parameter comparisons of the 9 different bearing types. It should be noted that the noise parameters in the table below refer specifically to the noise emitted by the fan bearings only, while the overall noise of the fan also depends on the design and the rotational speed of the fan blades.

Table 1: Comparisons of the 9 different bearing types.

From the above table, we can see that sleeve bearings and hydraulic bearings are still the bearing types used by

most cooling fans in the market due to their lower production process and manufacturing cost.

Although the service life of hydraulic bearings is only 40,000 hours, if calculated by running 10 hours a day, its

service life is as long as 10 years. Coupled with the low price, it is still very valuable for most people. However,

due to the complexity of the current fan brands, there are some shoddy phenomena, so when choosing, we should try to

choose those brands with better reputation.

For those players who have higher requirements on noise and performance, the current magnetic bearing is a very good

choice. Compared with ordinary hydraulic bearings, some magnetic bearing fans can also allow players to remove the

blades very conveniently to facilitate daily cleaning and maintenance.

Generally speaking, when we choose a cooling fan, we still have to adhere to the principle of "suitable for

ourselves", and choose a fan that suits our needs according to our budget and needs.