Figure 1: The worker is replacing the compressor in the fridge.

Some mechanic maintenance workers have noted that there could be some other faults after changing the compressor for the refrigerator. What are the causes? This article will give the reasons by introducing several cases.

In order to keep our article brief and easy to read, we will divide it into 2 parts. Here’s the first part.

When the test confirms that the compressor needs to be replaced, you should find the refrigeration compressors with the same manufacturer and specification through the nameplate. But in the actual situation, you have to use other brands or specifications of the compressor instead for some reason.

At present, the usual practice for compressor replacement is to estimate, which could generally work well for experienced workers. However, it is also difficult to meet the requirements of equipment working conditions and refrigeration standards.

Refrigeration Capacity of Compressor

The new compressor should be with the same refrigeration capacity as the compressor to be replaced. It is not accurate enough to focus on the compressor’s power. Although its power is related to the refrigeration capacity, it is not an indicator to measure the capacity.

For instance, some R600a high-efficiency compressors now have relatively large refrigeration capacity despite the small electric power of the motor.

At first, you should figure out what type the compressor is. There are commonly used compressors with low back pressure (LBP), medium back pressure (MBP), and high back pressure (HBP). The evaporation temperature range that the LBP compressor can achieve is -5 - 15℃, the MBP compressor is -15 - 0℃, the HBP compressors -5 - 15℃.

In the actual selection, you should not be confused. Otherwise, it will lead to poor refrigeration effects, or even damage the compressor.

For instance, the HBP compressor of the red wine cabinet should not be used in the refrigerator or freezer of LBP. It is unable to reach the temperature range of the refrigeration.

On the contrary, the LBP compressor should not be used in the HBP equipment. If not, it is easy to damage the compressor due to the mismatch of the capillary.

Figure 2: Danfoss compressor.

Case Study 1

A Galanz BC-103CQA1-53F refrigerator with R134A refrigerant was used in a hotel room. The refrigerator compressor failed and the refrigeration effect was poor after changing the compressor.

Analysis and Maintenance

The original compressor was manufactured by Danfu and the type is PW4.0VK. After checking, its refrigeration capacity is 112W and power is 91W. Due to the failure to purchase the same model compressor, we replaced a Wansheng QD65H compressor with a refrigeration capacity of 168W and a power of 147W.

We used to figure that high refrigeration speed and better effects are of the compressor with the larger refrigeration capacity. After filling the compressor with quantitative refrigerant according to the nameplate, we found that the exposed wire mesh condenser of back-hanging was extremely hot, so was the drying filter.

The evaporation and return temperature of the evaporator was high, and the overload protector of the refrigerator tripped when it worked for about 20 minutes. After the appropriate reduction of refrigerant, there is some improvement of the refrigeration effect but not enough.

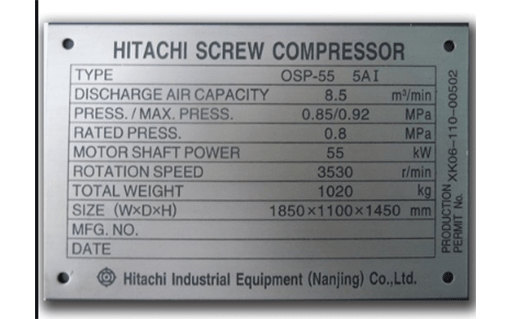

Figure 3: Hitachi screw compressor nameplate information, including type, discharge air capacity, press, power, rotation speed, weight, and size.

This case is due to replacing with a compressor of the larger refrigeration capacity, resulting in the mismatch of the compressor and other components (condenser, capillary) and poor refrigeration effect. After we replaced it with a Wansheng WV43H compressor (refrigeration capacity 111W, power 92W), the refrigeration returned to normal.

Summary

The refrigeration capacity above is measured by evaporation at 23.3℃ and condensing at 54.4℃ under the test condition. If users expect high requirements for performance and noise reduction, they can also choose higher grade ones manufactured by well-known brands such as Donper, Zanussi, Danfoss. The matching data are listed in table 1 below for reference.

|

No. |

Brand |

Type |

Refrigeration Capacity |

Power |

Price |

|

1 |

Danfu |

PW4.0VK |

112W |

91W |

Low |

|

2 |

Wansheng |

WV43H |

111W |

92W |

Low |

|

3 |

Donper |

S43CZ |

106W |

105W |

Medium |

|

4 |

Zanussi |

OF789 |

110W |

102W |

High |

|

5 |

Danfoss |

TL5G |

108W |

140W |

Extremely high |

Table 1: Parameters of compressors manufactured by Danfu, Wansheng, Donper, Zanussi, Danfoss.

Clean Piping System & Replace Drying Filter in Compressor

Once the compressor is damaged, you must clean and decontaminate the cooling piping system with dry nitrogen, and then replace the drying filter. After that, you could replace the compressor.

After using for a period of time, there will be dirt, sludge, and other substances in the refrigeration piping system. This will lead to the accumulation of dirt in the pipe wall of the heat exchange device, capillary, and drying filter, affecting the heat dissipation of the condenser and the heat absorption of the evaporator. It causes the effective diameter of the pipe to become smaller and more easily blocked.

Figure 4: Refrigeration piping system of multiple freezer cabinets.

In addition, the inner wall of the refrigeration pipeline is covered with frozen oil. To avoid old and new oil mixing to shorten the service life of the compressor after you replace the compressor, it is necessary to clean the system.

The drying filter absorbs moisture and filters impurities in the process of refrigeration. If it is of bad quality, it will also lead to the accumulation of dirt and sludge in the drying filter after a certain period of time. To extend the life of the new compressor, you would better replace the drying filter at the same time.

Case Study 2

The compressor of a Haier BS-226 refrigerated display cabinet went wrong. After replacing the compressor of the same manufacturer and specification, the refrigeration effect was not good, and there was condensation at the welding place between the drying filter and capillary tube.

Figure 5: Haier refrigerated display cabinet.

Analysis and Maintenance

The worker plugged in the power supply for trial operation, and there is a weak sound of flowing refrigerant in the evaporator. By touching the drying filter, the maintenance worker felt cold at the interface with the capillary, which should have been warm. Therefore, we preliminarily determined that the refrigeration system is a bit blocked.

To verify this guess, the worker turned off the power supply, and use a cutter (not gas welding) in the middle of the dry filter cut three minutes later. As a result, a large number of refrigerants erupted, which shows the dry filter or capillary is indeed blocked.

For the purpose of solving the problem thoroughly, we should clean at high- and low-pressure sides.

* High-Pressure Side

At the welding place between the compressor and the condenser, you should connect the nitrogen hose at the inlet of the condenser, adjust the pressure to 1.0Mpa. By flushing the system, you could flush out the residual dirt, oil, and mud in the pipeline from the condenser outlet.

* Low-Pressure Side

You should connect the nitrogen hose at the processing pipe of the compressor, adjust the pressure to 0.8MP. And you could cut off the connecting pipe between the drying filter and the capillary, open the valve of the pressure reducing gauge, and use nitrogen to wash the evaporator and the capillary under high pressure.

If there is a certain pressure and continuous airflow at the capillary, it means that the pipe is dredged. If it is a weak flow at the capillary outlet, the pipe is still blocked. Therefore, you should use a small steel wire through the capillary inner hole while adding nitrogen, which could be effective. It’s because the diameter of the capillary inner hole is small ( 0.6mm - 1.0mm) and easy to block at the entrance.

Tips

If the capillary inlet is blocked, it is not recommended to use pliers or scissors to remove a small section and dredge the pipe by shortening the capillary. Because this will change the pressure difference, improve the evaporation temperature of the evaporator and reduce the pressure of the condenser, improving the refrigeration temperature.

Related Info

Air Compressor Troubleshooting and SolutionsTop Central Air Conditioner Comparison for 2021 Summer - Trane vs Daikin vs Mitsubishi vs Carrier

How Does a Refrigeration Compressor Work - With Animation for Each Type

How to Reduce Noise of Air Compressor?

High Temperature Mulfunction of Screw Compressor and Solutions

Why Refrigeration Compressor Oil Deteriorates & How to Add Oil

Air Conditioner Refrigerant Leakage & Solutions

Variable Speed Compressor in Refrigerator

How to Check and Replace Refrigerator Compressor Relay