Figure 1: Mechanical arm in industrial automation.

Servo motor is an engine that controls the operation of mechanical components in the servo system, which is a kind of indirect speed change device to supplement the motor. It converts the voltage signal into torque and speed, can be divided into DC and AC servo motors.

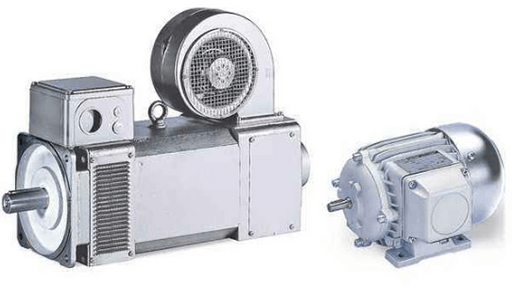

1. Siemens 1FT7 Servo Motor

The Siemens 1FT7 servo motor is a compact synchronous motor for high performance applications, which can meet the strict requirements of accuracy, dynamic characteristics, speed setting range, protection level and robustness.

1FT7 is equipped with the latest encoder technology and optimized for use with Siemens' all-digital drive and control systems. Cooling methods are divided into natural cooling, external cooling and water cooling.

Figure 2: Siemens 1FT7 motor.

Pros of 1FT7 Servo Motor

Four times overload capacity. High dynamic performance over a wide range of RPM Settings for natural cooling.

Superior work piece surface quality with the smooth running feature and minimal torque fluctuation.

Easy to install and maintain.

Due to the use of rotary connectors, cross guide rails, quick locking and shaping connectors, electronic nameplates, is is easy to replace the encoder on site without any adjustment.

2. Bosch Rexroth MSK Synchronous Servo Motor

Bosch Rexroth MSK series motors are characterized by wide power range and fine size classification. These synchronous servo motors have a high torque density with maximum torque up to 495 Nm (self-cooled). Two models of encoders are available depending on the required level of accuracy. Additional options such as keyway and brake, increased concentricity, IP65 protection rating, etc., enable the system to be used with fans, water-cooling units and ATEX.

Figure 3: Bosch Rexroth Servo Motor 2AD132D-B05OB2-AS03-B2N1

In 1978, Indramat, branch of Rexroth, officially launched MAC permanent magnet AC servo motor and drive system at the Hanover trade fair, which marked that this new generation of AC servo technology has entered the practical stage.

3. Lenze MCS Synchronous Servo Motor

Lenze MCS synchronous servo motors are designed for precisely controlled motions with torque ranges from 0.5 to 190 Nm (0.25 to 15.8 kW), especially for dynamic applications with high precision and minimum size requirements. MCS has high overload capacity and high rotation acceleration, and uses plug-in technology. It’s quick to install and easy to apply. Electronic nameplate of MCS is also easy to debug.

Rotating transformer as alternating feedback: incremental or absolute encoder, using high quality magnetic materials (SEPT technology) and specially developed polar format to increase power density, can support grip braking. In addition, MCS has protection class IP65 (forced air cooling IP 54), higher accuracy and energy efficiency advantages.

Figure 4: Lenze MCS synchronous servo motor.

4. Schneider Lexium MDrive Motor

Schneider Lexium MDrive integrated motor innovatively combines advantages of stepping motor and servo motor. It is compact and easy to install, so up to 50% of the total expenditure can be saved. In terms of technical innovation, Lexium MDrive integrates a variety of communications and control modes, including P/D, CANopen, Ethernet /IP, Modbus TCP and internal motion task, so that customers can choose flexibly.

At the same time, Lexium MDrive adopts the new Hybrid technology, which combines the advantages of stepping motor and servo motor, and gives full play to the advantages of low speed and high torque of stepping motor and automatic adaptation of servo motor.

Figure 5: Schneider Lexium MDrive motor

In addition, Lexium MDrive motor adopts closed-loop control. With high stability and low operating temperature, Lexium MDrive is more efficient and energy-saving. 4 years warranty period can reduce the maintenance cost of users.

5. AKM Series Servo Motor of Kollmorgen

Kollmorgen AKM servo motor has industry-leading performance and power density, low teeth, low harmonics to ensure smooth operation. It’s easy to use and automatically tuned with AKD drive. What’s more, AKM has a wide range of standard products and can provide joint research and development customization.

Figure 6: Kollmorgen AKM servo motor.

Features of Kollmorgen AKM Servo Motor

8 kinds of frame specifications, 28 kinds of frame/laminated combination

Rotation speed up to 8000 RPM

75 VDC, 120, 240, 480 VAC windings

All kinds of feedback equipment, installation accessories, sealing

Install directly to most Kollmorgen servo drives

When the ambient temperature is 40°C, and the rated winding temperature reaches 100°C, the servo motor is equipped with insulation material of Class F that can stand temperature of 155°C.

CURUS, CE certification, UL certification

6. Rockwell Automation Kinetix VP Servo Motor

Rockwell Kinetix servo motor provides smooth integrated motion control over Ethernet /IP networks. The Kinetix VPC runs the servo motor continuously and is optimized to run on the Kinetix 5700 servo drive providing continuous power and torque. The Kinetix VPL low inertia servo motor and the Kinetix VPF food grade servo motor can work in conjunction with the Kinetix 5500 and 5700 servo drives to provide high dynamic performance.

Figure 7: Kinetix VP servo motor.

Features of Kinetix VP Servo Motor

Provide real-time motor performance information to the control system through digital feedback equipment.

Optimized to match VFD ratings for efficient system specification determination.

A cable is used to provide feedback, motor braking and motor power.

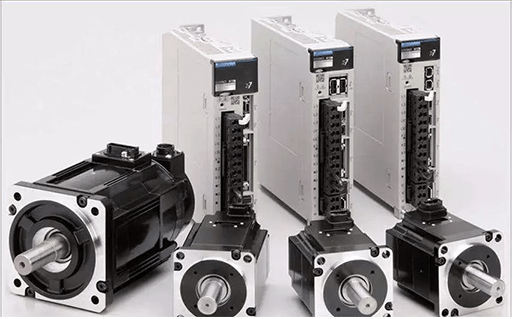

7. Yaskawa ∑-Ⅴ Series Servo Motor

Yakawa ∑-Ⅴ series (rotary type) servo motor has advantages of reliable distribution, oil and dust proof and so on. ∑-Ⅴ motor’s amplifier response is high, so it could greatly shorten the setting time which is one-twelfth the time of the company's previous products.

By adding and improving the vibration suppression function, the following performance can be improved and the setting time can be shortened. In addition, it can reduce the vibration (sound) when driving and the vibration of the mechanical front end when stopping, and improve the mechanical performance by combining the medium inertia motor.

Figure 8: Yaskawa ∑-Ⅴ servo motor.

Models of Yaskawa ∑-ⅤSeries

Yaskawa ∑-Ⅴ series includes the following models:

SGMJV(small capacity/medium inertia) : 100W~750W

SGMAV(small capacity/low inertia) : 50W~ 1.0KW

SGMPs (small capacity/medium inertia/flat shape) : 100W~ 1.5KW

SGMGV(medium capacity/medium inertia) : 300W~ 15KW

SGMSV(medium capacity/low inertia) : 1.0KW ~ 7.0KW

Yaskawa is a professional manufacturer in the field of motion control. It is the first company to do servo motor in Japan. Products of Yaskawa are famous for their stability, fast speed and high cost performance.

8. Mitsubishi HG-KR Servo Motor

Mitsubishi MELSERVO-J4 series servo motor uses a dedicated execution engine with an exclusive high-speed servo-control architecture, with a maximum response frequency of 2.5kHz. Combined with its proprietary high-resolution absolute position encoder (4,194,304 p/rev), it can largely increase the processing speed.

MELSERVO-J4 rotary servo motors consist of three series: HG-KR (low capacity, low inertia), HG-MR (low capacity, low inertia) and HG-SR (medium capacity, medium inertia).

Figure 9: Mitsubishi HG-KR servo motor.

9. Sanyo SanMotion R Servo Motor

Sanyo "SANMotion R" servo motor has quick action and instantaneous maximum torque of 18 N·m, which greatly reduces the acceleration deceleration time of the machine, thus improving the responsiveness of instructions.

The maximum speed is increased by about 33% to 6,000 min-1 and helps to shorten the production beat time and improve productivity. Due to the torque has high speed, even a small volume can obtain a large output. Compared with the previous products with same outoput, the overall length is shortened by about 23%, and weight is reduced by about 22%. SanMotion R is suitable for spring forming machines, printed circuit board drilling machines, robots, etc.

Figure 10: Sanyo SanMotion R servo motor.

Sanyodenki AC servo drive system, with its excellent performance, high speed, precision, flexibility, long service life, high cost performance, has been widely praised.

10. Delta ECMA Series Servo Motor

Delta ASDA series AC servo systems are based on core electronic technology and developed to meet the needs of customers for different application machines. The control loop adopts high-speed digital signal processor (DSP), with the design of automatic gain adjustment, command smoothing function and software analysis and monitoring, it can meet the requirements of high-speed displacement, precise positioning and other motion control.

The ECMA series servo motor developed in 2005 is an important model in the development of Delta AC servo system.

Figure 11: Delta ECMA series servo motor.

Features of Delta ECMA servo motor

Capacity range: 0.1KW ~ 7.5KW

Permanent magnet synchronous motor

Torque range: 0.32N·m ~ 47.74N·m

Speed range: 1000 r/min ~ 3000 r/min

Encoder type: 2500PPR, 17bit, 20bit

Order products: brake brake, oil seal, absolute encoder

Axle type: circular shaft, keyway

Related Info

TECO Servo JSDEP Works for Food Placement MachineBasics of Servo Motor You Should Know

Where is Servo Motor and Servo Drive Used?

Application of Servo System in Textile Machinery

Case Studies of TECO Servo Drive and Servo Motor

Why Does Servo Motor Vibrate?

How to Choose Pulse, Analog and Communication Control Modes of Servo Motor