Application of Piston Rod Settlement Monitoring System in Reciprocating Compressor

1. Introduction

A petrochemical plant imported a reciprocating compressor from abroad, the model is: B254-4118N3.3, 4 rows of symmetrical balanced type, the import and export parameters are:

135kPa (A)@14℃, 3.4MPa (A)@35℃, rotation speed: 425r/min, stroke: 240mm.

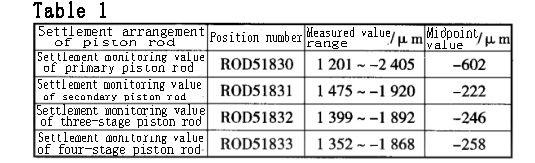

The unit is equipped with a piston rod settlement monitoring system. When foreign businessmen commissioned the unit, they gave the range of monitoring values for the piston rod settlement of the unit (Table 1). If this value is reached, it indicates that the support ring has worn a lot and must be stopped immediately, otherwise the piston and cylinder will be damaged.

Application of Piston Rod Settlement Monitoring System in Reciprocating Compressor

2. Monitoring principle

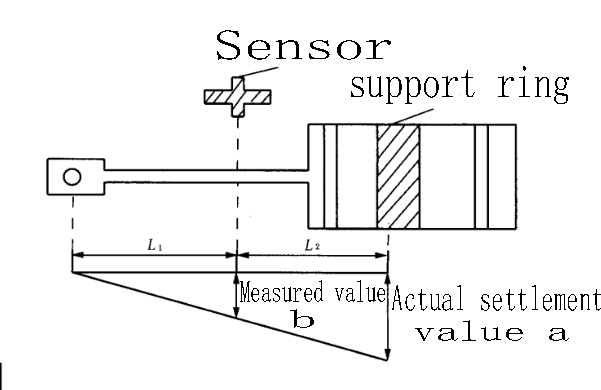

After the piston support ring is worn, the piston sinks, which causes the gap between the settlement sensor and the piston rod to change, and causes the gap voltage to change. The rod settlement value measured by the sensor is proportional to the amount of wear of the support ring. The specific measurement principle is shown in Figure 1.

Application of Piston Rod Settlement Monitoring System in Reciprocating Compressor

A=measured value B(L1+L2)/L1

Some specific unit parameters need to be input into the monitoring system for calculation, including connecting rod length, piston rod length, piston stroke and sensor positioning distance.

3. Operation

Among the parameters given by foreign companies, the first-level piston rod settlement monitoring value

ROD51830's high reported value is 1.5mm, and the second-stage piston rod settlement monitoring value

ROD51831’s high reported value is 1.4mm, and the three-stage piston rod settlement monitoring value

ROD51832's high reported value is 1.0mm, the four-stage piston rod settlement monitoring value

The high reported value of ROD51833 is 0.8mm.

In other words, the first-stage piston rod settlement monitoring value ROD51830 increases by 1 500 μm on the basis of the initial value of 602 μm, and when it reaches -2 102 μm, the value is reported as red. Details are shown in Table 2.

Application of Piston Rod Settlement Monitoring System in Reciprocating Compressor

After the unit has been running for a period of time, the secondary piston rod settlement monitoring value (ROD51831) turns red on the DCS, indicating an alarm. This indicates that the secondary piston support ring is worn, and the amount of wear has reached the high reported value of 1.4mm, and the support ring needs to be replaced at this time. After the alarm, the unit operated for a while. But to avoid grinding cylinders and

Accumulate experience and decide to shut down for maintenance.

Four, overhaul

After the shutdown, the compressor is fully measured. The data is shown in Table 3.

Application of Piston Rod Settlement Monitoring System in Reciprocating Compressor

1. Measure the gap between the cylinder block and the piston at all levels.

Measure at four points evenly distributed on the circumference between the cylinder and the piston, and take the values on the same line of the upper and lower parts of the piston. From the data point of view, the gap between the cylinder block and the piston ring of the secondary cylinder is not uniform, which is significantly larger than that of other cylinders. In particular, the difference between the upper and lower clearances of the piston is 1mm for the first stage, 4.1mm for the second stage, 0.5mm for the third stage, and 0.5mm for the fourth stage. It indicates that the support ring of the secondary piston has been severely worn, causing the piston rod to sink. The monitoring instrument ROD51831 alarm is correct.

2. Measure the thickness of the support ring.

From the measurement data in Table 3, the thickness of the support ring of the secondary piston has worn 2mm compared with the new ring, while the wear of the piston support ring of other cylinders is only 0.2mm.

3. Measure the thickness of the piston ring.

From the measurement data of the piston ring (Table 4), the piston ring is not worn.

Application of Piston Rod Settlement Monitoring System in Reciprocating Compressor

Five, data analysis

According to the information provided by foreign companies, the depth data of the compressor piston support ring groove and the size of the support ring are as follows (Table 5).

Application of Piston Rod Settlement Monitoring System in Reciprocating Compressor

It can be seen from Table 5 that the theoretical wear amount of the support ring of the secondary cylinder is 2.8mm. It is found that the support ring of the secondary cylinder has actually worn 2mm during the shutdown and maintenance.

0.8mm wear is available, but it is close to the wear limit, and the time for shutdown maintenance is appropriate.

From the measurement data, for safety reasons, the lower limit of the piston rod settlement value is relatively small by foreign companies. For example, the secondary piston rod settlement monitoring value (ROD51831) is 1 920μm, in fact, this value can be enlarged.

Six, improvement measures

Since the unit transports 1 600kg/h of hydrogen, the hydrogen is used in the downstream PSA device, and every additional day of operation can produce high economic benefits. In order to make the monitored value truly reflect the actual wear of the piston support ring and to ensure that the piston does not wear, the maintenance personnel need to pay attention to the following matters.

1. Before starting the unit, the zero point of the probe needs to be checked first. Make the starting point of the settlement value zero. This step can be implemented on the Bently instrument stand. If the starting point of the settlement value is less than zero, make sure that the starting point remains the same every time you adjust.

2. After the unit has been running for a period of time, the position of the piston in the cylinder will rise due to thermal expansion. After the unit has been running for about 4 hours under rated load, the zero point of the monitoring module should be reset.

3. From the calculation of settlement value A, company A=measured value B(L1+L2)/L1, it can be seen that connecting rod, piston rod length, piston stroke, sensor positioning, confirm

The scale factor (L1+L2)/L1 is calculated, so its accuracy must be ensured.

4. The piston rod will be slightly bent during reciprocating motion. At the same time, there is a gap between the crosshead and the slideway. During the reciprocating motion, the crosshead will be slightly upward.

Move down. These factors must be taken into consideration when adjusting the zero point.

Seven, operating cycle

Through a period of exploration, the monitoring value of the compressor piston rod settlement has been able to truly reflect the degree of wear of the support ring, and the compressor operating cycle has been extended from 6 months to 8 months. The next goal is to further optimize the piston rod settlement monitoring value through comparison with the measured data during maintenance, so that it can reflect the true wear of the support ring to the maximum extent, and increase efficiency for the enterprise.