Figure 1: Various types of water level meters.

Water level meters, also called "water level indicators" or "water level actuators," are widely used in industrial boiler. Because the water in the boiler is vaporized for heating at high temperature, and the loss of water and steam is large, it is necessary to continuously replenish the water to keep the water level in the boiler at a certain height. If the water level is too low, the boiler is in danger of explosion. In order to know the water level in the boiler at any time, a water level meter is installed on the boiler, and the water level gauge and the boiler form a communication device.

As an instrument for measuring water level, there are actually many types of water level meters, such as float level sensor, fiber optic level sensor, hydrostatic level sensor, and ultrasonic level sensor, with different working principles. Let's explain them one by one.

1. Types and Working Principles of Water Level Sensors

1.1 Float Level Sensors

The principle is to sense the rise and fall of the water level by the float.

Figure 2: Magnetic Float Level Sensor ATO-FS-MRDZ3, Stainless Steel.

There are different types of float level sensors. Some can directly make the float drive and record by mechanical means. And telex and digital level sensors that convert the angle of rotation provided by the float into incremental electrical pulses or binary coded pulses for long-distance transmission. What’s more, digital water level indicators composed of micro-floats and many reed switches.

Among them, the most widely used is the mechanical water level sensor. The application of float level sensors requires logging equipment, and they are only suitable for low-sediment river sections with stable bank slopes and little silt accumulation.

1.2 Fiber Optic Level Sensors

Fiber optic level sensors include the sensor part of the level sensor and the terminal part of the control circuit. The former adopts an optical path coupling adjustment device, connected with an optical cable to transmit an optical signal carrying water level information. The latter adopts laser modulation technology to send modulated laser signals with different functions, and obtain accurate information of water level through modulation, comparison and detection.

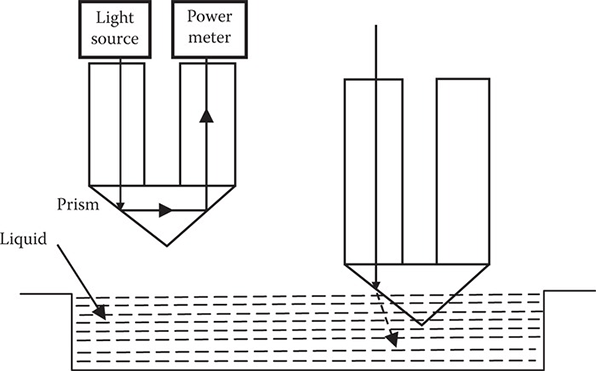

Figure 3: Working principle of fiber optic level sensors.

This principle realizes the whole-process optical measurement, and does not use any charged devices outdoors, to eliminate static electricity hazards and prevent lightning strikes.

1.3 Hydrostatic Level Sensor

Hydrostatic level sensors work by measuring the water pressure and estimating the water level. They feature no need of building hydrostatic logging, and the sensor can be fixed on the bottom of the river, so as to directly measure the water level by eliminating atmospheric pressure with pressure pipes.

There are two types of hydrostatic level sensors. One is the bubble type, which continuously transmits gas in the pressure pipe, and converts the water pressure into a mechanical angle with an automatically adjusted pressure balance, thereby driving the recording mechanism. The other is electrical measurement type, which uses solid-state piezoresistive devices as sensors, which can directly convert water pressure into voltage modulus or frequency output, and transmit it to the shore for processing and recording with wires.

1.4 Ultrasonic Level Sensors

An ultrasonic level sensor is a type of reflective water level sensor. It measures the water level by the principle that sound waves reflected from different interfaces. It is divided into two types: air-mediated and water-mediated. The air-mediated type uses air as the transmission medium of sound waves. The transducer is placed above the water surface, and the sound wave is reflected by the water surface and the water level can be calculated and displayed according to the echo time. The instrument does not touch the water body, and is completely immune to some unfavorable factors such as sediment, velocity impact and aquatic plants in the water.

Figure 4: Ultrasonic level sensor for water/fuel/oil/powder, 0-60M, ATO-LEVS-DP.

As for the water-mediated type, the transducer is installed on the bottom of the river and emits sound waves to the water surface. Acoustic waves travel in water with high speed and large distances, and well logging is not required. Both water level sensors can transmit information by cable to indoor display or storage records.

Related Info

What is a Blend Door Actuator?How to Replace a Blend Door Actuator?

What is a worm gear reducer

What is an Actuator?

Pros and Cons of Pneumatic, Electric and Hydraulic Actuators