Figure 1: Johnson Controls Actuator M9109-GGA-4.

From electronic access control systems, vibrators on cell phones and home appliances to vehicles, industrial equipment and robots, actuators are present in almost every machine around us. Common applications for actuators include electric motors, stepper motors, jacks, electric muscle stimulators in robotics, and more. Next, let's learn more about actuators.

1. The Constitution of Actuators

In the process control system, an actuator consists of the actuator part and the automatic adjustment mechanism. The automatic adjustment mechanism directly changes the parameters of the production process through the actuator component, so that the production process meets the predetermined requirements.

The actuator part accepts the control signal from the controller and converts it into the output of the drive adjustment mechanism (such as angular displacement or linear displacement output). It also uses appropriate actuators, but the requirements are different from the adjustment mechanism.

Actuators are installed directly on the production site, and sometimes require strict working conditions. Whether the normal operation can be maintained directly affects the safety and reliability of the automatic adjustment system.

2. How does an Actuator Work?

An actuator is a driving device that can provide linear or rotary motion. It uses a certain driving energy and works under the action of a certain control signal. Actuators utilize liquid, gas, electricity, or other energy sources and convert them into driving force through motors, cylinders, or other devices.

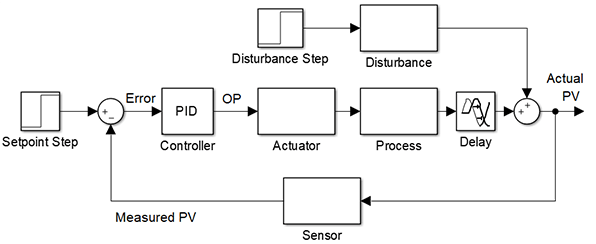

In the control system, the actuator refers to the device and component that directly controls the controlled object, i.e., it accepts the command signal of the controller, converting it into the corresponding action on the controlled object through the actuator part, changing the state of the controlled object in order to realize the process of control.

Figure 2: Voith Actuators are applied in control system.

If the sensor is compared to the sensory organ of the control system, the regulator is the brain of the control system, and the actuator can be compared to the hand that does specific work, and the controlled object is the object that the actuator acts on.

3. Types of Actuators

1. Actuators can be divided into three types: pneumatic, hydraulic and electric according to their energy sources.

Pneumatic actuators use compressed air as an energy source. They are characterized by simple structure, reliable and stable action, large output thrust, convenient maintenance, fire and explosion proof, and low prices, so they are widely used in chemical, paper-making, oil refining and other production processes.

Electric actuators have convenient energy access and rapid signal transmission, but have complex structures and poor explosion-proof performance.

Figure 3: Constitution of Tolomatic RSA cylinder electric rod actuator.

Hydraulic actuators are basically not used in chemical, oil refining or other production processes, and are characterized by a large output thrust.

2. According to the forms of displacement, there are two types of actuators: rotary actuators and linear actuators.

3. According to the law of action, the actuator can be divided into three types: switch actuators, integral electric actuators and proportional actuators.

4. According to the input control signal, the actuator can be divided into several types such as air pressure signal, DC current signal, electrical contact on-off signal, pulse signal and so on.

4. Applications

Electric actuators are mainly employed in the following three fields.

4.1 In Power Plant

Actuators are used in hydraulic push-rod drive, steam regulating valves, ball and butterfly valve controls, and sliding doors for thermal power industry applications. And in other power industries, they are used as valve actuators, for example, in ball valves, gas control valves, burner ignition start, condensate water recirculation, overheating controller, etc.

4.2 In Process Control

Actuators are used for production process control in chemical, petrochemical, mold, food, pharmaceutical, packaging and other industries. They precisely position, start and stop, open and close, and rotate for valves, tools, pipes, baffles, chutes, platforms, etc., according to established logic instructions or computer programs.

Figure 4: Block diagram of actuators’ role in process control.

They also use the real-time parameters such as temperature, pressure, flow, size, radiation, brightness, chromaticity, roughness, density detected by the system to adjust the system, so as to realize the control of intermittent, continuous and cyclic processing.

4.3 In Industrial Automation

Actuators are widely used in aviation, aerospace, military, machinery, metallurgy, mining, transportation, building materials, etc. They adjust and control the moving points (moving parts) of various automation instruments and systems in various forms.

Related Info

How to Reduce Gear Noise?6 Types of Commonly Used Gear Reducers

What is a worm gear reducer

What is a Gear Reducer?

What is Gear Ratio?