Common sense of micro vacuum pump

The so-called vacuum refers to a gas state with a pressure lower than 101325Pa in a given space. In the vacuum state, the lean degree of gas is usually expressed by the pressure value of the gas. Obviously, the smaller the pressure value, the thinner the gas. There are various vacuum pumps in the industry. There are prescribed test methods for the performance of various pumps. The main parameters are:

1. Ultimate vacuum (usually called vacuum degree): Connect the vacuum pump to the detection container, put the gas to be tested, and perform continuous pumping for a long time. When the gas pressure in the container no longer drops and maintains a certain value, This pressure is called the ultimate vacuum of the pump. The smaller the value, the closer to the theoretical vacuum.

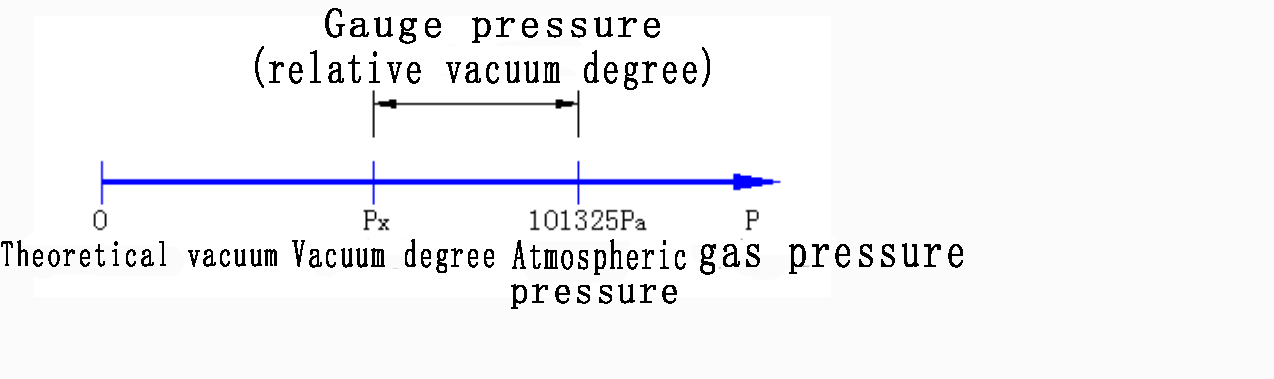

The vacuum value (ie, gauge pressure) measured by an ordinary vacuum gauge is the relative vacuum degree, expressed as a negative number, which refers to the difference between the measured gas pressure and the atmospheric pressure. It can be seen from the figure below.

2. Pumping rate: the volume of gas flowing through the unit time at the suction port of the vacuum pump. Traditional industrial vacuum pumps are generally large in size, and the work of the pump requires special vacuum pump oil and lubricating oil, and the medium gas contains a lot of oil mist. With the development of the instrumentation industry and people's requirements for environmental protection, miniature oil-free vacuum pumps in various countries have emerged. There is generally the following law: the price of the pump is closely related to the vacuum index. The vacuum index is the main index that manufacturers in various countries are striving to pursue. It reflects the overall strength of the corresponding mechanical processing, sealing technology, material science and other fields, and is also an important means for manufacturers to obtain profits. To improve the vacuum index, it is necessary to have higher sealing conditions. Therefore, it is necessary to use parts with more precise dimensions and better material properties, so the production cost is greatly increased. And the price increase is far greater than the increase of the vacuum index. Of course, the increase in the pumping rate will also cause the price to rise, but the increase is not large. Therefore, when choosing a miniature vacuum pump, you need to carefully consider the vacuum index, pumping rate index, and your own usage, so that you can take into account the performance and cost.

The high vacuum micropump uses very precise sealing parts, so it has higher requirements for the clean conditions, temperature parameters, and medium composition of the working environment.

Vibration and noise. The higher the pumping rate and vacuum degree of the pump, the greater the vibration and noise.