1. What is an Encoder

Encoder is a kind of equipment that can compile and convert signals or data into signals that can be used for communication, transmission and storage. Encoder converts angular displacement or linear displacement into electrical signal, which is called code disk and code ruler respectively. It is a common motor positioning equipment in industry, which can accurately test the angular displacement and rotation position of the motor.

Figure 1: Yaskawa Encoder ECN1113

2. Types of Encoders

According to the working principle, encoder can be divided into two types: incremental encoder and absolute encoder.

Incremental encoder converts displacement into periodic electrical signal, then converts this electrical signal into counting pulse, and finally, the number of pulses is used to represent the displacement.

Each position of the absolute encoder corresponds to a certain digital code, so its indication is only related to the starting and ending positions of measurement, and has nothing to do with the intermediate process of measurement.

2.1 Incremental Encoder

Incremental encoder usually has three outputs, which are A-phase, B-phase and z-phase. The pulse output of phase A and phase B is delayed by 1/4 cycle. According to the delay relationship, the forward and reverse can be distinguished. Furthermore, the frequency can be doubled or quadrupled by taking the rising and falling edges of the A and B phases. The Z phase is a single cycle pulse, that is, one pulse per cycle.

The grating of incremental measurement consists of periodic grating bars. The position information is obtained by calculating the number of increments (measurement steps) from a certain point. Because the absolute reference point must be used to determine the position value, the circular grating encoder has a reference point track.

2.2 Absolute Encoder

The absolute encoder corresponds to one turn, and each reference angle emits a unique binary value corresponding to that angle, which can be recorded and measured at multiple locations by an external ring device.

When the encoder is energized, the position value can be immediately obtained and readily read by the subsequent signal processing electronic circuit without moving the shaft to perform the zero reference operation.The absolute position information comes from the circular grating code plate, which consists of a series of absolute codes.Individual incremental rail marking signals generate position values through subdivision and also generate optional incremental signals.

The absolute position value information of the single-turn encoder is repeated every turn.The multi-turn encoder can also distinguish the position values of each turn.

Figure 2: Disc grating for absolute rotary encoder.

2.3 Differences between Incremental Encoder and Absolute Encoder

In the case of incremental encoders, the position is determined by the number of pulses calculated from the zero mark, while the position of the absolute encoder is determined by the output code.The output code is unique for each location in a circle. Therefore, when the power supply is disconnected, the absolute encoder is not separated from the actual position.If the power supply is switched on again, the output code indicating the position is still current and valid, unlike incremental encoders, which must look for zero marks.

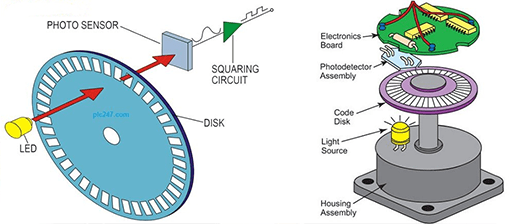

3. Work Principle of Encoder

The encoder obtains four groups of sine wave signals which are combined into A, B, C and D signals.The signal is obtained from a centrally axed photoelectric code plate with a circular notch and photoelectric emission and reception devices.

Each sine wave has a phase difference of 90 degrees (360 degrees relative to a circumferential wave). Stable signals can be enhanced by superimposing C and D signals on A and B phases in the opposite direction.In addition, a Z-phase pulse is output per revolution to represent the zero reference bit.

Figure 3: Structure and work principle of encoder

Because the phase difference between a and B is 90 degrees, we can distinguish the forward and reverse rotation of the encoder by comparing whether phase A is in front or phase B is in front. We can also get the zero reference bit of the encoder through the zero pulse. The material of the encoder code disc is divided into glass, metal and plastic.

The glass code disc is a thin engraved line deposited on the glass, which has good thermal stability and high precision. The metal code disc has both through and impervious lines. It is not fragile, but because the metal has a certain thickness, the accuracy is limited, and its thermal stability is much worse than that of glass. The plastic code disc is economical, and its cost is low, but the accuracy, thermal stability, and life are worse.

Figure 4: Dynapar Encoder HA625050006101

4. Principle of Position Measurement and Feedback Control

In elevator, machine tool, material processing, motor feedback system and measurement and control equipment, encoder plays a very important role.

The encoder converts the light signal into TTL (HTL) signal by using grating and infrared light source through the receiver, and then visually reflects the rotation angle and position of the motor by analyzing TTL level frequency and number of high levels.

Because the encoder can measure the angle and position accurately, we can make up a closed-loop control system with the encoder and the frequency converter to make the control more precise. This is why elevators, machine tools, etc. can be used so accurately.

5. Summery

To sum up, we know that the encoder is divided into incremental and absolute according to the structure. They also convert other signals, such as optical signals, into electrical signals that can be analyzed and controlled. The common elevators and machine tools in our life are precisely based on the precise adjustment of the motor, through the feedback closed-loop control of the electrical signal. It is natural that the encoder and the frequency converter realize the precise control.

Related Info

Factors to Consider When Selecting Rotary EncodersMaintenance of Absolute Encoders

When You Should Use an Absolute Encoder - Pros and Cons of Different Absolute Encoders

How to Install Encoders - Best Practices

How to Add Encoder to Stepper Motor