Figure 1: The cutaway view of herringbone gear oil pump.

1. Selection Principle of Gear Pump

When selecting and using gear pumps and gear motors, the indicators of various technical performance parameters should be strictly controlled within the specified scope of the instruction manual. Let's take a look at the selection principles of gear pumps!

1.1 Speed of Gear Pump

The speed of the gear pump should be selected according to that of the prime mover, and the rated speed of the gear pump must be larger than or equal to the normal working speed of the prime mover. The instantaneous peak speed of the prime mover must not exceed the maximum speed specified by the pump, and if so for the sliding bearing, it will heat up and burn due to excessive rotation speed.

1.2 Rotation Direction of Gear Pump

According to the rotation direction of the prime mover, select the gear pump with the same rotational direction. The rotation direction of the gear pump is determined when it leaves the factory, and it is marked with a lead seal, and the user is not allowed to disassemble and change it.

1.3 Displacement of Gear Pump

Select the displacement of the gear pump according to the required flow. Since the gear pump is a fixed displacement pump, the excessive flow will not only cause unnecessary power loss, but also cause the system to heat up and fail.

When determining the flow rate, in addition to considering the working flow of the system, the flow leakage loss of other hydraulic components should also be fully considered, and the volume efficiency of the gear pump will decrease slightly after wear, which will affect the normal operation of the system. This contradiction is particularly prominent in the selection of small displacement gear pumps.

Figure 2: Gear pump performance curve.

1.4 Working Pressure of Gear Pump

The normal working pressure of the hydraulic system should be less than or equal to the rated pressure of the hydraulic gear pump, and the short-term pressure peak should not exceed the maximum pressure. Reasonable selection of the gear pump working pressure is one of the most important factors in determining the life of the oil pump.

The life of the gear pump depends on that of the bearing, and the life of the bearing is short if the load is large. Especially for the gear pump with the sliding bearing structure, if the pressure exceeds the specified pressure a lot, the bearing of the pump and the gear shaft will seize up instantly.

You can choose suitable gear pumps according to different pressure levels: low pressure ≤ 2.5MPa, medium pressure 8~14 MPa, medium and high pressure 16~20 MPa, high pressure 21~31.5 MPa.

1.5 Anti-Pollution Ability of Gear Pump

The anti-pollution ability of the gear pump depends on its structure. If it is a gear pump with fixed side clearance and rolling bearings, an oil filter with lower filtration precision can be selected, while the gear pump with radial clearance compensation and sliding bearing structure, is highly sensitive to contamination, and oil filters with higher filtration precision should be selected.

Figure 3: Analysis diagram of gear pump radial force.

1.6 The Medium to be Transported by Gear Pump

Select according to the characteristics of the medium to be transported. For example, in the case of transporting high-viscosity liquids, the clearance of the gear pump should not be too small. If it is too small, the gear pump is easy to heat up and be locked, and the mechanical efficiency will be reduced, which will affect the overall performance of the pump.

When transporting high-viscosity liquids, it is particularly critical to choose a suitable rotational speed. If the rotational speed selected is too fast, it is easy to generate air suction, the noise of the pump is large, and the flow rate cannot meet the requirements. If the rotation speed selected is slow, you need to choose a large pump to meet the requirements, which is not economical.

If the gear pump is used to transport corrosive media, it is necessary to select the gear pump made of materials that are resistant to the corrosion of this media.

2. Problems That Should be Paid Attention to When Reinstalling a New Hydraulic Gear Pump

1. Do not add load immediately to the hydraulic gear pump after starting.

After the hydraulic gear pump is started, it must be idling for a period of time without load (about 10 minutes to 30 minutes). Especially when the temperature is very low, it must go through the warm-up process to make the hydraulic circuit circulate normally and then add load, and confirm the operation status.

2. Pay attention to the noise of the hydraulic gear pump.

The new hydraulic gear pump has less initial wear and is easily affected by air bubbles and dust. Poor lubrication at high temperatures or overloaded operation will cause adverse consequences and make the hydraulic gear pump produce abnormal sounds.

3. Pay attention to observing the action of the machine (for the modified pump).

Improper design of the hydraulic circuit or poor manufacturing of components are not easy to find in the initial use stage, so special attention should be paid to the action state that appears under various operating conditions.

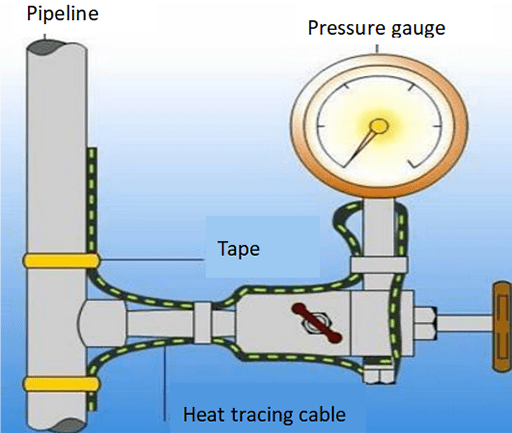

4. Pay attention to checking the display value of the instruments.

Observe the display value of the pressure gauge of the hydraulic circuit, the vibration status and stability of the pressure switch signal light at any time, so as to find out whether the hydraulic circuit is functioning properly as soon as possible.

Figure 4: Pressure gauge connected to pipeline system.

3. What Should I Pay Attention to When Using a Gear Pump?

The gear pump is suitable for various industries and transports a wide range of media. It has the advantages of firm structure, convenient installation, easy disassembly, simple maintenance, uniform and continuous flow, slight wear, and long service life.

How long do gear pumps last? From the usual experience, it is usually about 1 year to 1.5 years, and some can be used for 2-3 years. This question cannot be answered accurately, because the life of the gear pump is affected by its own quality factors and also has a great relationship with the actual working conditions. Continuous work at peak values every day, oil cleanliness and other reasons can affect the service life of the gear pump.

1. In the process of using the gear pump, it is necessary to add lube frequently. The grease is easy to volatilize, so you must pay attention to that, and secondly, keep the bearing clean.

Figure 5: Needle roller bearing for gear pumps.

2. During or after the use of the electric oil pump, it should be placed in a relatively dry, non-corrosive and clean environment.

3. Check and maintain the gear pump frequently during the use process. Pay attention to checking whether the power cord, internal wiring, plug and switch can still be used normally; whether the bearing parts are damaged or not.

4. Every part of the gear pump should be preserved. During the process of disassembling and inspecting the gear pump, every part should be preserved and kept clean.

4. Summary

The first principle to be followed in gear pump selection is applicability. It is not that the higher the precision of the gear pump, the better, and the smaller the clearance, the better. The pump to be selected is the best as long as it is suitable for the working conditions. What kind of product is called a good product? No matter how good the product is, if it is not suitable for working conditions, it is also a wrong choice!

If you need a professional engineer in gear pump selection, you can contact us. Professional engineers have a detailed understanding of the applicable working conditions of the pump, and can help you choose a pump that meets your on-site working conditions with suitable performance parameters.

In addition, our website is able to offer a wide variety of hydraulic gear pumps and hydraulic gear pump parts, such as small hydraulic gear pump. If you are interested, please feel free to contact us.

Related Info

Structural Characteristics of Gear Pump and Its Working PrincipleHow to Select a Hydraulic Pump

Hydraulic Pumps: Common Faults and Troubleshooting Methods

Gear Pumps: Working Principle, Types, Pros&Cons and Applications

Common Faults and Troubleshooting of Gear Pumps