Figure 1: Human Machine Interface (HMI).

In nearly any assembly line, or manufacturing plant, employees work with touchscreens every day. This link between man and machine is a Human Machine Interface, or HMI for short. Much like a keyboard and monitor to a desk-jockey, this HMI is a vital component to any assembly line and when it goes out, so does productivity. So, it is necessary to learn about how to install a HMI.

1. How to Install a HMI

1.1 What do We Need

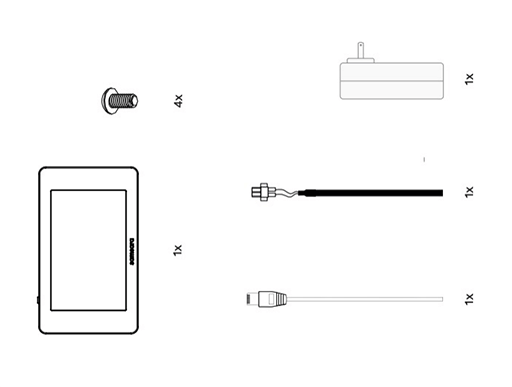

HMI; 4 button head bolts #3; 1 ethernet cable; 1 trial power cable; 1 trial power supply.

Figure 2: What we need.

It is recommended that you buy an industrial power supply (24V) to wire HMI into power. Get 4.5 mm drill bits to drill the holes into the panel.

1.2 HMI Installation Steps

Drill holes into the panel through the paper slip with your 4.5 mm drill bits. Cut the square hole of the paper slide out of the panel so you can wire the HMI up in the back through the panel, then screw the button head bolts #3 from the backside to properly mount your HMI

Figure 3: Cut the square hole and screw button head bolts.

Connect the ethernet cable and the power cable (and screw it in) into the back of the HMI. Then, connect the power supply and turn HMI on.

Figure 4: Connect the ethernet cable and the power cable into the back of the HMI.

2. 4 Common Failure of HMI

While touchscreens can be fickle devices, their dysfunctions can generally be grouped into one of three categories:

2.1 Touch Panel Failure

This can be from wear and tear, or a failure between the resistive material between the layers of the screen. This is a common problem seeing as the touch panel takes the most physical “abuse" of the device.

Figure 5: A HMI suffered touch panel failure.

2.2 Display Failure

LCD, LED and backlights can go out at any point of a device’s use. These can be repaired through a video-panel replacement, or even something as simple as replacing a backlight.

2.3 Main Board Failure

This is getting into the nitty-gritty portion of the device, though these boards can be as complex as a computer’s board, to something as small as a display drive, but it’s still getting into the guts of your HMI.

Figure 6: A HMI suffered main board failure.

2.4 Power Supply Failure

Finally, capacitors and fuses can go out. This can be a problem when your electronics probably need electricity. It’s a simple fix, but one that can happen multiple times over your equipment’s lifespan.

While the problem may seem like no brainers, it is also recommended to repair it with a professional.

Related Info

How to Test a Transformer?What is a Transformer?

Classification and How Does a Transformer Work?

10 Common Types of Transformer?

Transformers Selection and Buying Guide?