Air compressors can provide stable air flow with little pressure fluctuation, which has the advantages of stable rotation and high efficiency. It is the auxiliary production facility of many industrial enterprises and plays an important role in production.

As an instrument of loud noise in the first place, the strong noise produced by an air compressor during operation may deteriorate the working conditions and living environment of people. How to reduce the noise of air compressors is a common problem in industrial noise control.

This article will give you some solutions. First of all, you need to find out the source of the noise.

1. Noise Source Analysis

Air compressor is a multi-source sound generator, whose noise mainly includes intake noise, exhaust noise, mechanical noise, and electromagnetic noise.

1.1 Intake Noise

Intake noise is an aerodynamic noise generated by pressure pulsation when the air compressor intermittently inhales air. It is a kind of broadband continuous spectrum and has the characteristic of low frequency. The sound pressure level gradually decreases from low to high frequency. The low frequency of intake noise is strong, the frequency band is wide and the total sound pressure level is high. Generally, the noise increases with the rise of load, which is 7-10dB(A) higher than that of other parts and is the main noise source of the air compressor.

1.2 Exhaust Noise

Exhaust noise is caused by the disturbance of airflow when the gas is discharged intermittently from the air compressor cylinder valve. It is also a kind of broadband continuous spectrum. However, the spectrum is obviously medium and high frequency. The noise frequency is relatively complex, whose total sound pressure level is generally between 80 and 110dB(A).

The exhaust noise is related to the flow, the pressure of compressed gas, and the speed of the air compressor. The larger the flow, the higher the pressure and the speed, the greater the noise. As the outdoor exhaust port is generally arranged, it has a great impact on the surrounding environment.

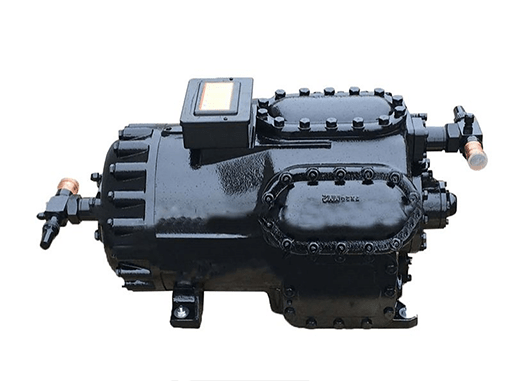

Figure 1: Mitsubishi Compressor ADB78FAAMTS

1.3 Mechanical Noise

Mechanical noise is caused by friction, wear, and uneven force transmission between mechanisms, especially due to the imbalance of the rotor system. Therefore, the noise’s frequency is an integral multiple of the rotor’s rotation frequency. Its fundamental frequency is the same as that of the intake noise, and its frequency spectrum is also low frequency. The noise sound pressure level is generally 90 - 110dB(A).

1.4 Electromagnetic Noise

Electromagnetic noise is the noise caused by the magnetic field pulsation of the drive motor. It has a wide frequency band and a stable sound pressure level.

2. General Methods of Reducing the Noise

Generally, three methods of noise control are sound absorption, sound insulation, and noise elimination. If the surrounding is a vibration-sensitive building, vibration control will be adopted. Generally, the method of installing a muffler or other noise elimination device is adopted to control the intake noise of the air compressor.

If a muffler is used, you would better select the resistance muffler with low frequency and low intermediate frequency broadband. If the air compressor inlet is indoor, the muffler shall accomplish a noise reduction of about 15dB (A). If outdoor, the noise reduction, generally not less than 20dB (A), should be reduced to the requirements of environmental noise standards. The exhaust noise of an air compressor with high exhaust pressure and large flow rate is high, and a special muffler shall be set to control it.

Figure 2: Bristol Compressor H20B133ABC

The muffler is required of a large amount of noise reduction, wide noise band, pressure expansion, and pressure drop reduction of the exhaust vent to reduce the noise of the exhaust vent. The noise attenuation in the medium and high-frequency range with a wide frequency band can be obtained by using the resistance muffler. For the purpose of achieving the total frequency band noise reduction, the impedance compound muffler can be applied.

The body noise and motor noise of an air compressor are controlled through sound insulation and sound absorption. For instance, you could increase the sound insulation of the enclosure structure of the air compressor room by adding sound-absorbing materials or structures to the inner wall structure surface. The equipment heat dissipation should also be considered.

3. Specific Methods of Reducing the Noise

We figure that the noise reduction of air compressors is mainly realized by the muffler, silencing tunnel, and sound insulation technology.

3.1 Installation of Muffler

The main noise source of the air compressor comes from the intake/exhaust port, so it’s important to select the appropriate intake/exhaust muffler. The noise spectrum of the air compressor inlet presents a low frequency, so the muffler of impedance composite structure should be chosen. Because of the high air pressure and the high gas flow velocity at the exhaust port, a small hole muffler should be selected.

Figure 3: Hitachi Compressor 1501FSVW6-T

3.2 Setting Silencing Tunnel

The silencing tunnel is underground or semi-underground. The wall of the tunnel is made of bricks with excellent sound absorption performance. By connecting the air inlet pipe of the air compressor with the silencing tunnel, the air can pass through the silencing tunnel first, and then enter the air compressor to achieve the purpose of reducing noise.

3.3 Setting Acoustic Enclosure

You could reduce the airflow noise to below 80 dB by installing a muffler or setting a silencing tunnel at the inlet/outlet of the air compressor. However, in addition to the airflow noise, the air compressor also makes high mechanical noise and motor noise, which can be effectively eliminated by installing an acoustic enclosure on the air compressor unit.

3.4 Suspension Absorber

In many air compressor rooms, the machine noise will reverberate with the wide workshop. At this time, it is necessary to lay sound absorbers on the roof of the plant, which can reduce the noise of the plant by 3-10 dB and reduce the reverberation time.

![Type: Semi-hermetic S Refrigerants: R22 LRA[A]: 74.1 No.of cyclinder: 2 Nominal power[HP]: 5 Discharge[m3/h]: 26.8 Voltage: 380-400V 3P 50Hz 440-480V 3P 60Hz](https://okmarts.com/jeecg-boot/sys/common/view/temp/magefan_blog/202105/Copeland Compressor 2CS-500-TFM-min.png)

Figure 4: Copeland Compressor 2CS-500-TFM

As general machinery, air compressors are widely used in various industries. But the high noise, and high energy consumption, have become an obvious problem. The problem affects the quality of air compressor products a lot. Besides, eliminating the noise of air compressors can greatly improve people's livelihood and reduce environmental pollution.

People living near the factory could be troubled by the noise of mechanical equipment. Workers in factories are also exposed to noise. Taking noise pollution level as the index of assessing factory and living environment has long been included. Air compressor suppliers also have the responsibility and obligation to reduce the noise pollution in the process of operation, creating a better working and living environment.

Get Quotation for Quality Air Compressors on OKmarts