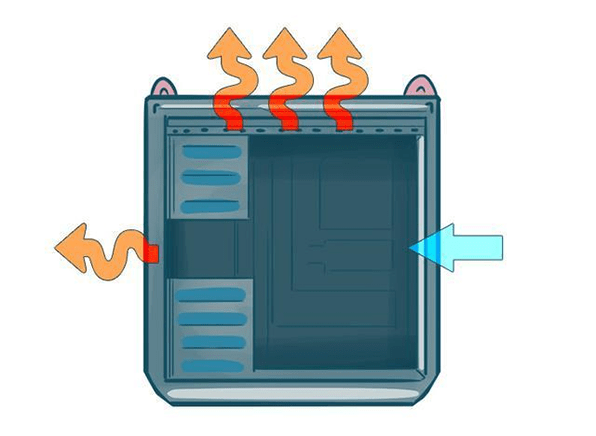

Figure 1: PC case.

The power supply, CPU, chipset, memory, and graphics card in the computer case can generate a lot of heat. If the

chassis air channel design is not reasonable, it will not be able to effectively dissipate heat. The air channel is

a very important part of the cooling capacity of the chassis, and a good chassis air channel design can effectively

improve the overall cooling effect.

What is the best chassis air channel design? What are the main points of the chassis air channel design? How should

the chassis air channel go? Today, the editor sorted out the relevant knowledge about the design of the chassis air

channel. Let's learn together.

1. Types of Case Airflow Channel Design

At present, there are three types of chassis air channels commonly used in the market: horizontal air channels, vertical air channels and three-dimensional air channels.

1.1 Horizontal Type (Fans at Front, Rear, and Bottom or Top of the Case)

In this kind of computer case, the cold air enters from the front panel and the bottom of the case, and the hot air is discharged from the back of the case. The chassis of this design is simple in structure and low in cost, and the heat dissipation effect is not bad when there are not many parts in the computer.

Figure 2: A typical horizontal airflow channel chassis.

However, there will be heat dissipation blind spots on the upper front and lower rear of the chassis, which is a relatively obvious shortcoming.

1.2 Vertical Type (Fans at Top and Bottom of the Case)

There are few cases with vertical air channels on the market, and the fan at the bottom of the case needs to

forcibly draw the cold air in, and then draw the hot air out through the fan at the top of the case. This design

effectively reduces heat build-up in the graphics card and power supply section.

In addition, the positive pressure air channel concept adopted in the vertical air channel design brings better dust

prevention effect. Because the air intake is larger than the output air in the positive pressure air channel, the

air can only flow into the chassis from the intake fan. Strengthening the dustproof effect at the air inlet of the

positive pressure chassis will be significantly better than the dustproof effect of the negative pressure chassis.

Figure 3: A typical vertical airflow channel chassis.

1.3 3D Type (Fans on Front, Rear, Top, and Bottom of the Case)

The three-dimensional air channel is actually the combination of the horizontal air channel and the vertical air

channel, combining the functions of the two at the same time. The biggest feature is that there are air holes in the

front, the rear, the top and the bottom. The multiple air inlets and outlets ensure sufficient air flow, and the

heat flow will be faster naturally.

There is still controversy about the effect of this kind of air channel. The advantage is that the blind area of

heat dissipation is small and the air volume is large. The corresponding disadvantage is also obvious, that is,

there are too many air channels in the chassis, which may cause mutual interference between the air channels,

resulting in turbulent flow and affect the heat dissipation effect. It also increases the difficulty for users to

build airflow channels.

Figure 4: A typical three-dimensional air channel chassis.

2. How Should the Chassis Air Go?

First of all, two concepts about chassis heat dissipation should be mentioned: positive pressure difference and

negative pressure difference. Positive pressure difference means that the air volume of the chassis inlet is greater

than that of the air outlet, and negative pressure difference means that the air volume of the chassis outlet is

greater than that of the inlet.

For example, install two fans on the chassis panel to take air in, and install one fan on the rear of the chassis to

exhaust air to the outside of the chassis, which is a simple positive pressure difference heat dissipation.

2.1 Positive Pressure Chassis

With positive pressure air channel design, hot air will be exhausted from the chassis through all cooling holes and gaps. Another advantage of this kind of air channel is that the only way for dust to enter the chassis is the fan at the air inlet. If you add a filter here, you don't have to worry about the problem of dust.

Figure 5: Positive pressure chassis.

2.2 Negative Pressure Chassis

The negative pressure air channel is just the opposite of the positive pressure air channel mentioned above. Its

principle is to let more air out of the chassis than air in, so that the air pressure inside the case is lower than

the outside, and more cold air can enter the chassis from holes and gaps to bring heat away.

The disadvantage of this kind of air channel is also obvious, that is, more dust enters the case, and it needs to be

cleaned frequently. At present, some small chassis with relatively compact structure and some high-end chassis adopt

this design.

Generally speaking, the positive pressure difference is easier to form a directional air channel, so the heat

dissipation effect of it will be better than that of the negative pressure difference. But sometimes the negative

pressure difference can also achieve ideal heat dissipation, depending on the specific chassis structure and

application scenarios.

Figure 6: Negative pressure chassis.

3. Conclusion

Common air channels are basically forward in, rear out, bottom in and top out. If the installation of chassis fans

at the bottom and front panel, it must be the air intake, while the top and rear of the chassis are generally air

exhaust places. Therefore, it must be clear which fan is used for air intake and which is used for exhaust. A messy

air channel can greatly reduce the cooling effect of your case. But for ordinary users, basically one exhaust fan

plus one intake fan is enough.

Note that in the multi-fan design, if fans are added to the side (right or left) of the chassis, it is easy to

disturb the internal air channels of the chassis, because the multi-fan chassis itself already has many air

channels, and the processor and graphics card also have their own fans. If fans are installed on the side of the

chassis, The entire air channel circulation is easily disturbed. Therefore, the installation of the side fan must be

considered carefully!