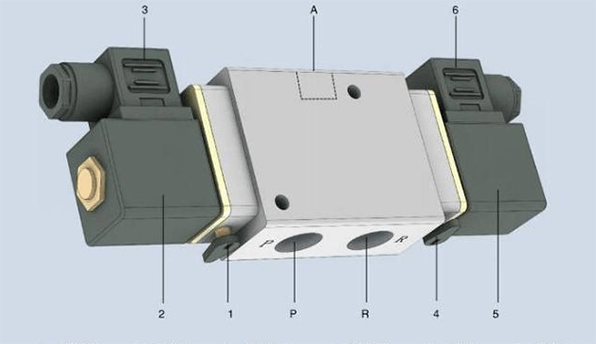

1: Manual knob 1 2: Solenoid coil a 3: Connector a 4: Manual knob 2 5: Solenoid coil b 6: Connector b P: Air source pressure chamber R: Exhaust chamber A: Working chamber

Pneumatic solenoid valve (also called air solenoid valve) is a device that controls pneumatic actuators (such as cylinders, turbines) and is widely used in industrial automation systems. It controls the air / gas flow, pressure and direction by controlling the on-off of electromagnet. This article will introduce in detail the structure, working principle, wiring diagram, etc. of the pneumatic solenoid valve.

1. Pneumatic Solenoid Valve Structure

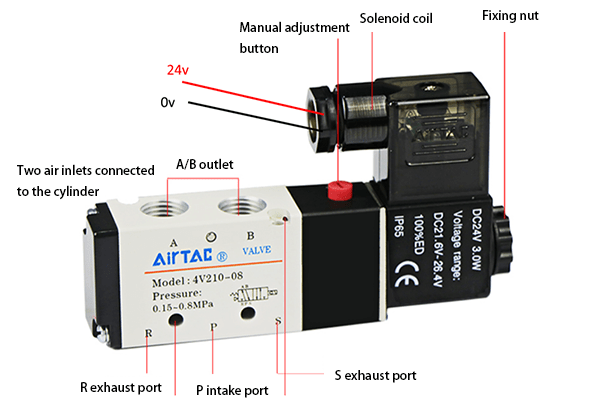

The pneumatic solenoid valve is composed of several parts including valve body, valve core, solenoid coil, spring and sealing gasket.

Solenoid coil: A coil wound by wires, when energized, generates a magnetic field to control the opening and closing state of the valve. According to the voltage and current used by the coil, solenoid valves are divided into DC solenoid valves (24VDC) and AC solenoid valves (110VAC or 220VAC).

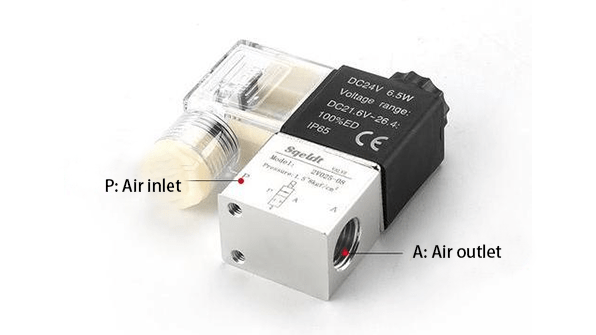

Valve Body: It is the main part that supports the solenoid coil and holds other components in place. There are air inlet, air outlet, and air exhaust ports on the valve body, through which the fluid enters or leaves the valve body.

Valve core: Through the action of electromagnetic force, it is attracted or pushed away to control the opening/closing state of the valve. The valve core is a component that directly controls the state of the solenoid valve.

Spring: The spring is the driving force for the valve core to return. When the solenoid coil de-energized, the spring pushes the valve core back to its original position.

Sealing gasket: It prevents fluid leakage and ensures the sealing performance of the valve. Air leakage between valve body components will affect the normal operation of the solenoid valve.

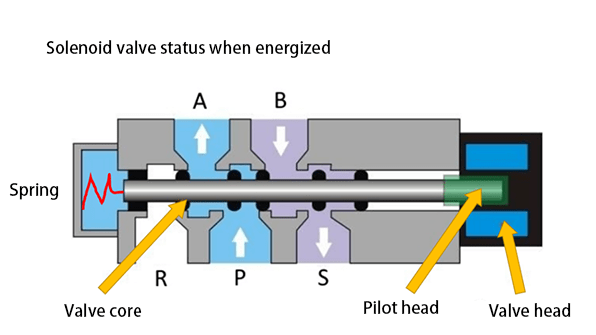

2. Working Principle of Pneumatic Solenoid Valve

When the solenoid coil is energized, the generated magnetic field attracts the valve core to move, thereby controlling the opening or closing of the air channels and achieving the regulation of the air.

The status of the solenoid valve when energized is as follows:

The status of the solenoid valve when de-energized is as follows:

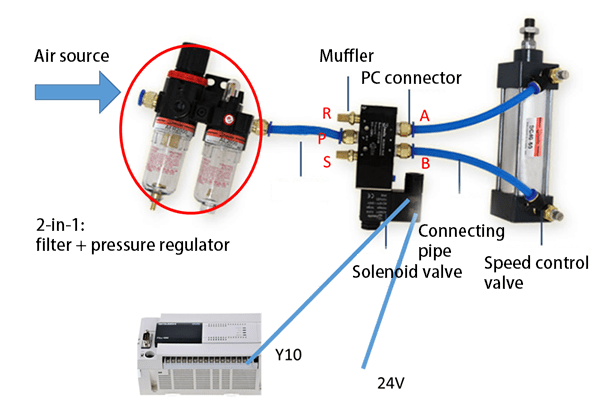

3. Pneumatic Solenoid Valve Symbols and Wiring Diagram

3.1 Pneumatic Solenoid Valve Symbols

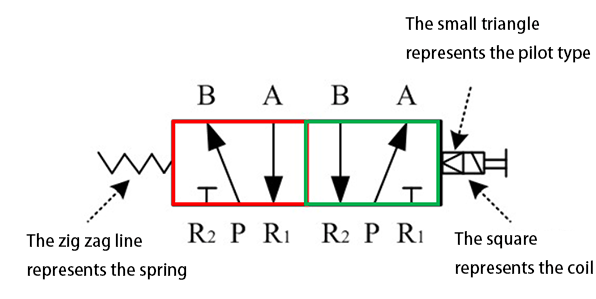

There are 2 boxes in the picture below, representing “2 positions”, and there are 5 ports, referring to “5 ways”, that is, the 2-position 5-way. The red box on the left indicates the state of the solenoid valve when de-energized, and the arrow indicates the air flow direction, while the green box on the right indicates the air flow direction when the solenoid valve energized.

P: Air inlet

R1: Air exhaust port

R2: Air exhaust port

A: Cylinder air inlet 1

B: Cylinder air inlet 2

3.2 Pneumatic Solenoid Valve Wiring Diagram

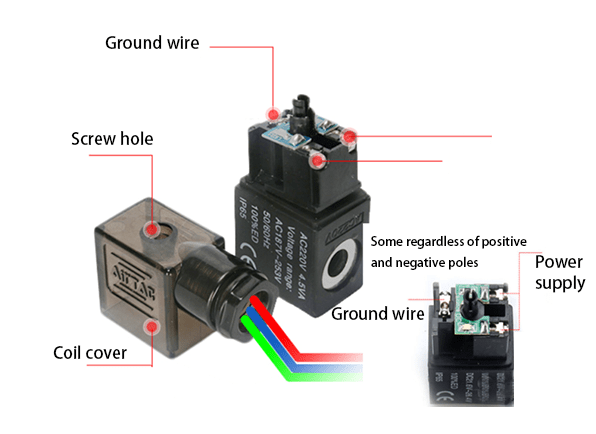

The power supply for the solenoid valve is 12V, 24V, etc., and the wiring diagram is as follows. Pay attention to the positive and negative poles of the power supply wiring, and reverse connection will cause the valve to not work.

4. Pneumatic Solenoid Valve Types

4.1 According to the Working Principle

Pneumatic solenoid valves can be divided into two types: direct-acting and indirect-acting (pilot-operated).

Direct-acting solenoid valve: It is composed of valve core, coil, spring, etc. When the coil is energized, the magnetic field force generated directly drives the valve core to move without pilot air flow. It has simple structure and reliable action, but requires larger drive current.

Indirect-acting solenoid valve: It consists of two parts: main valve and pilot valve. The pilot valve controls the action of the main valve. When the coil is energized, the pilot valve opens or closes, and makes the main valve core operate to control the opening or closing of the air channel. Pilot-operated solenoid valve requires smaller drive current and has higher control accuracy.

4.2 According to the Number of “Positions” and “Ways”

Pneumatic solenoid valves can be divided into: 2-position 2-way, 2-position 3-way, 2-position 5-way, 3-position 5-way, etc.

The number of “positions” and “ways” of solenoid valves refers to that of working states of the solenoid valve (2 or 3 working positions) and that of ports in the valve body (including the number of air inlets, air outlets and air exhaust ports). Among them, "positions" indicates how many working states the valve has, and "ways" indicates the total number of ports on the solenoid valve body.

For example, a two-position two-way solenoid valve has two working states (the coil is de-energized, and the coil is energized). It has 1 air inlet, 1 air outlet, and no air exhaust port.

4.3 According to Operation Type

Pneumatic solenoid valves can be divided into: normally open (NO) and normally closed (NC).

When the normally closed solenoid valve loses power, the solenoid valve is shut off, the air outlet is not connected to the air inlet, and there is no air in the air outlet; when the power is on, the solenoid valve is opened, the air outlet is connected to the air inlet, and there is air in the air outlet.

When the normally open solenoid valve loses power, the solenoid valve is opened, the air outlet is connected to the air inlet, and there is air in the air outlet; when the power is on, the solenoid valve is shut off, the air outlet is not connected to the air inlet, and there is no air in the air outlet.

5. How to Properly Clean Pneumatic Solenoid Valves

Preparation Work before Cleaning

1. Disconnect the pneumatic solenoid valve from the power and air source, and remove it;

2. Check whether the appearance of the pneumatic solenoid valve is damaged or corroded. If necessary, replace the corresponding parts in time;

3. Prepare cleaning fluid. Generally alcohol or cleaning agent can be used;

4. Prepare tools: brush, clean cloth or paper towel, cleaner, etc.

Cleaning Steps

1. Remove pneumatic solenoid valve;

2. Soak the pneumatic solenoid valve with a cleaning agent. Do not let the cleaning agent enter the coil to avoid affecting the valve service life;

3. Use a soft brush to gently scrub the surface of the pneumatic solenoid valve. Do not use a hard brush to avoid damaging the surface of the valve body;

4. For some stubborn stains, you can use a cleaner to clean them, but pay attention to controlling the pressure of the nozzle to avoid excessive pressure from damaging the valve body;

5. Use a clean cloth or paper towel to dry the pneumatic solenoid valve to avoid oxidation caused by moisture residue;

6. Carry out assembly, inspection and testing to ensure the normal operation of the pneumatic solenoid valve.

Precautions

1. When cleaning the pneumatic solenoid valve, be careful to prevent cleaning agent from entering the coil and causing short circuit or oxidation;

2. When using a cleaner for cleaning, pay attention to controlling the pressure of the nozzle to prevent damage to the valve body;

3. When reinstalling the pneumatic solenoid valve after cleaning, pay attention to the installation position and connection method of each component to ensure that it is correct;

4. Regular cleaning of the pneumatic solenoid valve can effectively extend the service life and avoid failures caused by long-term use.

In short, the correct cleaning method is of great significance for the maintenance of pneumatic solenoid valves. We hope the above steps can help you to keep your pneumatic solenoid valve in the best working condition.

6. Things to Note When Selecting Pneumatic Solenoid Valves

1. Working Medium: Determine the working medium of the pneumatic solenoid valve according to actual needs, such as air, nitrogen, etc.

2. Working Temperature: Determine the working temperature of the pneumatic solenoid valve according to actual needs to ensure its normal operation.

3. Working Pressure: Determine the working pressure of the pneumatic solenoid valve according to actual needs to ensure its normal operation.

4. Installation Method: Determine the installation method of the pneumatic solenoid valve according to actual needs, such as pipeline connection, flange connection, etc.

5. Brand and Specifications: Choose a reliable pneumatic solenoid valve brand and specifications on the market to ensure its performance and stability.

6. Energy Saving and Environmental Protection: On the premise of meeting functional requirements, try to choose a pneumatic solenoid valve with high energy efficiency and environmental protection.

7. Maintenance: Regularly inspect and maintain the pneumatic solenoid valve to extend its service life.

8. Training and Operation: Operators need professional training to ensure that they can correctly use and maintain pneumatic solenoid valves.

In short, the pneumatic solenoid valve, as an important fluid control component, plays an important role in industrial automation and process control. Understanding its structure, working principle, types, cleaning and selection precautions will help to better apply and maintain pneumatic solenoid valves, and improve production efficiency and equipment reliability.