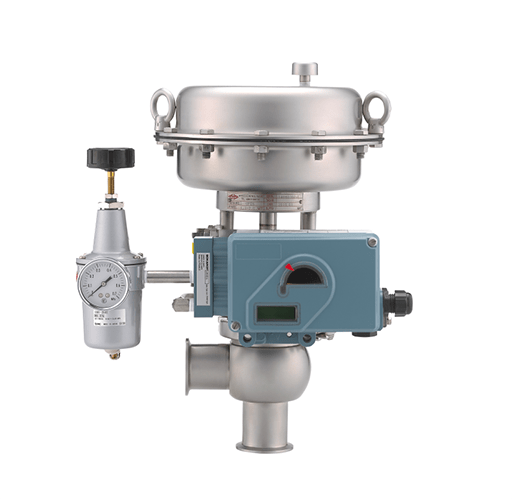

Figure 1: Proportional Valve.

When it comes to proportional valves, they are well-suited to a number of different applications in machinery, basic processes and hydro-pneumatic systems. They provide compact and cost effective solutions for controlling pressure or flow at low flow rates.

With so much differentiation and sources of supply, it is important to ensure you are picking the correct proportional valve to suit your application.

1. Proportional Valve Set Points

The first things to consider are:

• What are the flow ranges the valve is likely to experience?

• What are the maximum and minimum pressures that the valve is likely to experience?

2. Static Set Point Proportional Valve

Pressure or Flow will be Fixed With Infrequent Changes.

Typical Applications:

• Spot welding – where a valve is used to control pressure to a cylinder that applies the pinching force. The pressure will be set dependant on the material type and thickness being welded and will remain fixed until the machine is set up for a different material.

Figure 2: Spot welding.

• Leak testing – where a fixed pressure is applied to a component to check for soundness. The pressure will generally be fixed for a specific type of component but has provision for adjustment when the application is changed.

3. Dynamic Set Point Proportional Valve

Pressure or Flow will Change at a High Frequency.

Typical Applications:

• Pressure control valves connected to cylinders operating a flight simulator. Signals from the simulator control system constantly adjust the pressure in the cylinders to move the simulator cabin.

Figure 3: A pressure control proportional valve.

• Material testing where the pressure output of a valve is steadily increased until the material under test fails.

4. Step-By-Step Point Proportional Valve

Pressure or Flow will change but at a Low Frequency.

Typical Applications:

• A filling system where, as the container being filled approaches the required fill level, the flow rate is adjusted down so that the final filling happens at a lower rate.

• The control of gas to a burner on a cooker. This application would require different flow rates of gas dependant on the amount of heat required.

5. Adjusting Set Point Proportional Valve

Another consideration when selecting a valve may be the means by which you want to adjust the setting, whether that is a set pressure or a set flow rate. As discussed above, the set point can be static, dynamic or‘step by step’.

Some valves enable you to adjust the set point by sending an analogue control signal over the power cables or by using some sort of fieldbus communications.

Others have a local interface

Some enable you to communicate with the device via a PC and an RS 232 interface (this enables a far greater degree of tuning and optimisation to take place.

Figure 4: Proportional valve which adjusting set point.

6. Actuation of Operation of your Proportional Valve

Engineers should also consider the type of operation they require. Different operation methods for proportional valves could be:

Proportional solenoids: valve position is adjusted based on a varying voltage across the coil. The higher the voltage the greater the magnetic current and the more the valve spindle moves. It tends to give short response times and has an extremely low hysteresis.

Pulsed solenoids: uses small solenoid valves that load and unload pressure in a control chamber, allowing the valve to open and close.

Pneumatically operated and controlled by a positioner: When looking at larger capacities and larger flow rates it may be necessary to move to a valve fitted with a positioner. The positioner acts as a pilot, enabling air to enter and vent from a diaphragm or a cylinder which enables the much larger valve to operate.

Related Info

What is a Proportional Valve?Proportional Solenoid Valve - How They Work

How to Install a Sump Pump Check Valve: 5 Steps

How To Repair a Pool Spring Flapper Check Valve?