What are the principles of air compressor frequency conversion How to apply

As we all know, the application of frequency conversion air compressors on the market is becoming more and more extensive. With the rapid development of permanent magnet frequency conversion technology, the application of frequency conversion machines is still expanding. Many people may have the following questions: What is the frequency conversion of an air compressor? How does the air compressor achieve frequency conversion? How does variable frequency air compressor realize energy saving?

The so-called frequency conversion is to change

01. The meaning of air compressor frequency conversion

The power supply frequency of the motor means variable speed drive. Air compressor frequency conversion can bring many benefits. It can reduce the starting current of the motor, reduce the impact on the user's grid, automatically adjust the load, reduce power consumption, reduce losses, and extend the service life of the equipment.

02. How to realize air compressor frequency conversion

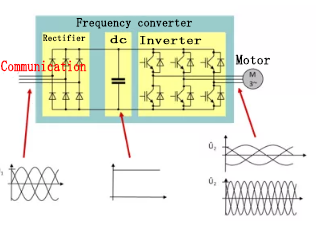

The frequency conversion technology is to rectify and filter the power frequency alternating current into a stable direct current through a rectifier circuit, and then invert it into an adjustable frequency alternating current (generally up to 400Hz) through the inverter circuit, and finally output to the variable frequency motor. The output frequency of the inverter is proportional to the motor speed. Taking a 4-pole motor as an example, when the output frequency is 20Hz, the motor speed is 600rpm, the output frequency is 50Hz, and the motor speed is 1500rpm. When combined with an air compressor, when the gas consumption in normal working conditions is large, the motor input frequency is high, the rotation speed is high, and the gas output is high; when the gas consumption is small at noon, the motor input frequency is low, the rotation speed is low, and the gas output is small.

03. How does variable frequency air compressor realize energy saving

Generally, users will consider the maximum production conditions when selecting the installed capacity of the air compressor.

However, the actual operating conditions only reach 60; 80% of the maximum gas consumption, or even lower. The traditional fixed-speed air compressor adopts loading and unloading control technology. In order not to stop when the air consumption is not large, the unloading operation is used to reduce the number of start and stop of the motor. The motor idling does not produce compressed air in the unloaded state. The power consumed at this time is called Unloading power is actually a waste of energy.

When the air compressor adopts frequency conversion control, it is different. The frequency conversion air compressor automatically adjusts the motor speed according to the actual air demand of the production to achieve air volume adjustment.

When the air volume is reduced, the air compressor automatically reduces the speed to reduce Power consumption; realizing that the gas produced by the air compressor matches the gas demand of customers from time to time, and no unloading loss is a major advantage of frequency conversion, as shown in the figure below.

What are the principles of air compressor frequency conversion? How to apply? "

It should be reminded here that the inverter is not energy-saving under all working conditions. As shown in the figure above, the energy-saving effect of the inverter is not so obvious when it is running at or near full load. If the user's air consumption is very stable and almost unchanged, then it is more appropriate to choose a high-efficiency fixed-speed air compressor, of course, this situation is relatively rare. It can be seen that the right selection has room for energy saving.