Figure 1: The air compressor of a car.

As hot summer is coming, air compressor maintenance workers will also usher in the busiest season of the year. Among air compressor malfunctions, high temperature failures occur most. So do you know what are the causes of overheating of the air compressor, and how to take measures to avoid it?

Air Compressor Lubricating Oil

* Insufficient oil

In the fixed-frequency load operation or the varied-frequency full-load operation of the air compressor, if the oil level is lower than the marked line L or MIX, the oil quantity should be insufficient. It would lead to a larger lubricating oil load and lower heat exchange efficiency, which causes the overheating of the compressor. At this time, you should add some oil.

* Oil deterioration

Due to various reasons, compressor oil will oxidize and deteriorate in the process of use, leading to poor oil fluidity and decreased heat exchange capacity. It would cause that the heat of the air compressor head can not be taken away completely and timely.

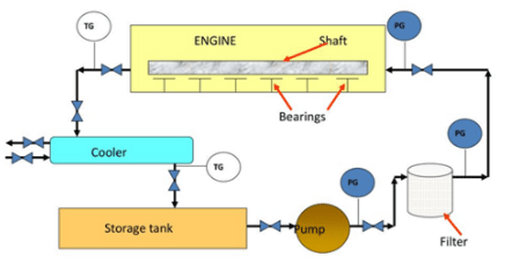

Figure 2: Lubricating system of a compressor.

* Incorrect selection

The selection of the compressor oil should be focused on the viscosity and quality under the guidance of professional and regular air compressor oil manufacturers.

Air Compressor Coolers

There are air coolers and water coolers according to their different cooling methods, and the corresponding is air-cooled compressors and water-cooled compressors.

* Dirty and blocked air cooler

After running for a long time, the air cooler is contaminated by impurities such as battling and dust in the air, and over time, the cooler will be blocked. The internal structure is also easy to be affected due to the accumulation of oil fouling and blockage.

* Cooler fan failure

The fan fails to work normally, resulting in the insufficient cooling effect of the cooler. For instance, the declined fan speed or stop working will affect the cooling effect, which should be maintained timely.

* Contaminated cooler

The metal ions in the cooling water with poor quality would calcify and produce scale and other impurities that will adhere to the inner wall of the water cooler. And after a long time of use, it will slowly clog the cooler and affect the heat dissipation effect.

Figure 3: An air compressor cooler.

* Cooling water

Low pressure, a small amount, temperature, and other factors of cooling water will cause the machine to overheated. Generally, the inlet pressure should be more than or equal to 0.25Mpa, the cooling water should be close to neutral, or the pH value should be between 6.5 and 9.5, the inlet water temperature should be less than 30°C, the temperature difference between inlet and outlet water is generally 5~ 10°C. The specific pressure of cooling water should be adjusted according to the operating temperature of the machine to achieve a better cooling effect.

You should clean the cooler in time according to the on-site using environments to achieve the cooling effect and escort the good operation of the compressor.

Compressor Temperature Control Valve

The temperature control valve is installed in front of the oil cooler and its role is to maintain the head exhaust temperature. If the thermal control valve fails, the lubricating oil may enter the head directly without passing through the cooler, thus failing to lower the oil temperature and resulting in high temperature.

Compressor Temperature Sensor

The temperature sensor failure could lead to a false alarm of the high temperature. You can remove the temperature sensor and detect it with boiling water and take a look at the changes in the temperature displayed on the panel.

Small Compressed Air Station or Unreasonable Layout of the Air Guide Hood

The compressed air station space is small. The improper layout of the air guide hood will cause the heat generated by the compressor to fail to be evacuated in time, resulting in the high ambient temperature of the station and thus the high temperature of the compressor. Before the construction of a compressed air station, it is necessary to reserve enough heat dissipation space and maintenance space between different equipment and between equipment and wall in advance. Besides, the station should maintain good ventilation, and add an air guide hood for exhaust when necessary.

Figure 4: A compressed air station.

Oil Filter Blockage

The compressor oil filter is blocked, affecting the supply of oil, impeding the normal circulation of oil, and leading to poor heat exchange effect of equipment and high temperature.

Compressor Head Failure

The air compressor head fault causing high temperature, in which the wear of the air compressor head leads to more heat and increasing temperature. On the other hand, the compressor oil level control system is abnormal. It can control the oil injected into the compressor. Insufficient oil will cause the overheating of the compressor. In such a situation, you should contact the after-sales personnel for professional adjustment and maintenance or guidance.

After learning about the causes of common high temperature failure of the air compressor. So how can we prevent high temperature malfunction of the air compressor?

When designing the station, you should keep enough heat dissipation and maintenance space, and maintain good ventilation. Besides, the environment should be dust-, heat-, and water-proof, so as to maintain a good environment for the station.

Improve the daily use and maintenance management level of the equipment, including daily maintenance and drainage, dust removal and inspection, and make records. You should add grease to the motor regularly as required and refer to the equipment manual for details.

Ensure regular maintenance. Replace filters, the oil, and other vulnerable parts according to the requirements of the equipment regularly.

For machines with bad working conditions and heavy load, it is best to wash the cooler or prepare a spare one and make regular online testing.

Case studies

Case 1

A water-cooled compressor has been malfunctioned by the high temperature, which is more frequent in hot summer. It may cause a jump in serious cases.

Maintenance

By asking for details, the maintenance worker found that the cooler has not been washed after several years of use. After cleaning the cooler, the temperature varied from 100 ℃ to about 80 ℃. The user should clean the cooler when the compressor is under routine maintenance.

Figure 5: The cooler before and after being cleaned.

Case 2

An air compressor was overheated seriously. After series of inspections, it was found that the oil filter base is blocked, which affects the flow of lubricating oil, leading to insufficient lubrication and high temperature of the compressor.

Maintenance

Clean the base of the oil filter.

Figure 6: The oil filter before and after being cleaned.

This article has summarized seven reasons for air compressor overheating, as well as two failure cases. I hope this would help you in the use of your air compressor.

Related Info

How to Reduce Noise of Air Compressor?High Temperature Malfunction of Screw Compressor and Solutions

Air Compressor Troubleshooting and Solutions

List of Problems and Solutions for Centrifugal Air Compressor