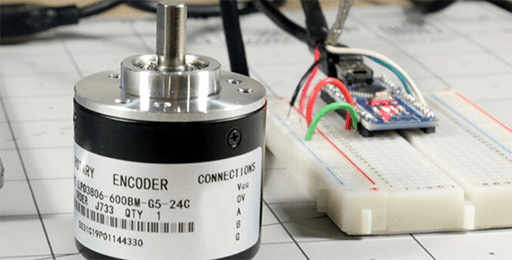

Figure 1: Encoder.

Encoders are critical components in all kinds of mechanical systems. They are especially prevalent in industrial settings where large machinery performs repeatable tasks, high-precision prototyping or delicate work.

1. Encoders for the Electronics Industry

Encoders are critical to the production of advanced electronics, one of the fastest growing and advancing industries in the world. Rotary, angle and linear encoders are all used in one form or another in the electronics sector. Encoders of the highest accuracy and resolution are often the choice considering the small work areas and components—especially when it comes to semiconductor fabrication.

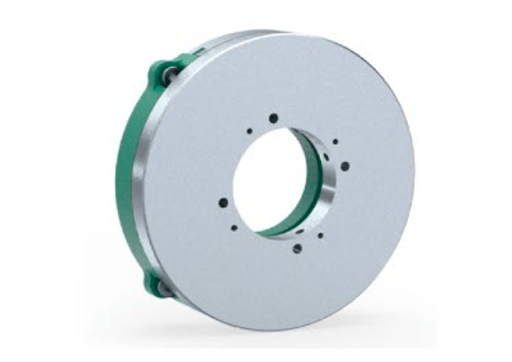

Figure 2: Rotary encoder (suitable for vacuum environment).

Vacuum environments are also common in electronics production. Encoders, including angle and linear, need to be built specifically for the unique ventilation, gas and temperature conditions that come with work in a vacuum.

2. Encoders for CNC Machining

CNC machines must maintain position in the face of heavy work pieces and spindles, multi-axis movement and high speeds. Encoders play a huge role in all of the components working together to mill, drill and bore correct parts. We also have a full line of popular control systems and touch probes used to program CNC machines.

3. Encoders for Automation

The automation industry is booming, and it couldn’t be without capable encoders. Robotic arms, like this one developed by grinding machine company, Strausak, are ubiquitous in manufacturing environments. Any unmanned mechanical systems will rely on consistent and accurate motion and measuring.

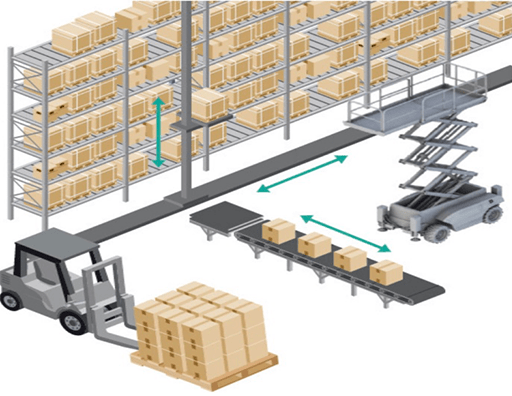

Figure 3: Application for automate transportation.

Encoders are also being used to automate transportation as with Sweden’s high-speed train, the SJ3000, which employs a custom-made, absolute MC 400 encoder from Leine Linde. It helps operate a redundant system that controls the train’s speed and braking automatically if necessary.

If you’re looking for encoders for an automation application, use our product selector tool to narrow down your search.

4. Encoders in the Medical Industry

Figure 4: Application for medical industry.

Encoders are prominent in the medical industry because of the precision necessary to accurately and safely test and treat the human body—and develop new procedures in the lab. Some encoders are used in CT and MRI scanning machinery for help with precise imaging and patient safety. Radiation therapy is another application that requires precise linear and angular technology with no room for error.

5. Encoders in Robotics

Whether it’s an articulating arm that picks and places equipment in a manufacturing plant or more mobile, automated, guided robots, they all use encoders. By their nature, automated systems need these effective speed and positioning feedback systems to function with limited human assistance. In many cases, encoders with a small profile are best suited for a robotic design, so that all the required technology can fit together in a robot that’s sized appropriately to its use. The RENCO R35i and RCML 15 rotary encoders, for example, have height profiles of only 14 and 8.9 mm respectively.

6. Conclusion

Encoders all serve the same general purpose of measuring motion and signaling feedback, but their configurations, capabilities and applications vary widely. They have played a significant role in almost every facet of life, especially industrial and technological pursuits. And that won’t be changing any time soon.

Related Info

What is an Encoder?6 Common Faults of Encoder?

Different Types of Encoder and Their Differences?

10 Common Types of Transformer?

What is an Encoder?