There are three control modes of servo motor: pulse, analog and communication. In different application scenarios, how should we choose the control mode of the servo motor?

Figure 1: Servo motor and servo drive.

1. Pulse Control Mode of Servo Motor

In some small stand-alone equipment, the use of pulse control to achieve motor positioning should be the most common application. This control method is simple, easy to understand.

The basic control idea: the total amount of pulse determines the motor displacement, and the pulse frequency determines the motor speed. PLC uses high-speed pulse output port to send operation pulse signal to the pulse input port of servo motor. After the servo motor is enabled, PLC sends running pulse to the servo motor, and the servo motor can run.

1.1 High Speed Pulse Connection Mode

Figure 2: Different ways of high speed pulse connection.

If the PLC output signal is in the differential way, it can be used in Mode 1, which has the advantages of strong anti-interference ability of the signal and can be transmitted for a long distance. If the distance between the driver and the PLC is long, this method is recommended.

The PLC side adopts source output. European system PLC more use this way wiring, such as Siemens.

1.2 Types of Pulse Control

Open the servo motor manual, there will be a table. They are all pulse controls, but do not opeatare the same way.

Table 1: Three pulse control modes of servo motor.

* 2-Phase Pulse with 90°Phase Difference Pattern

The drive receives high-speed pulses of two circuits (A and B), and the direction of rotation of the motor is determined through the phase difference of the two circuits. As shown in the figure above, if B is 90 degrees faster than A, it is positive rotation. If B is 90 degrees slower than A, it is A reversal.

During operation, the two phase pulses of this control are alternating, so we also call this control mode differential control. It has the characteristics of difference, which also shows that this control mode has a higher anti-interference ability for pulse control. In some applications with strong interference, this mode is preferred. But in this way a motor shaft needs to occupy two high-speed pulse ports, which is not applicable to the tension of the high-speed pulse port.

* Positive Pulse Train Plus Negative Pulse Train Pattern

The drive still receives high-speed pulses of two circuits, but they do not exist at the same time. When pulse is in the output state of one circuit, the other one must be in the invalid state. When choosing this control mode, it is important to ensure that only one pulse is coming out at the same time. Pulses of two circuits, one output for the positive direction, the other for the negative direction of operation. As in the above case, this method also requires a motor shaft to occupy two high-speed pulse ports.

* Pulse Plus Symbol Pattern

Only one pulse signal is needed to drive, and the positive and negative operation of the motor is determined by the IO signal in the one direction. This control mode is more simple, and the high-speed pulse port resources occupy the least. In general small systems, this approach is preferred.

2. Analog Quantity Control Mode of Servo Motor

Figure 3: Work pricicple of analog control mode.

In the application scenario where the servo motor is needed to achieve speed control, we can choose the analog quantity control mode, and the value of the analog quantity determines the running speed of the motor. Analog quantity can be selected in two ways, current or voltage.

2.1 Voltage Analog Quantity Mode

It only needs to add a certain size of voltage in the control signal end, and in some scenes you can even use a potentiometer to achieve control, it is very simple. However, when the voltage is used as the control signal, it is easy to be disturbed in the complex environment, resulting in unstable control.

2.2 Current Analog Quantity Mode

The corresponding current output module is required. The current signal has strong anti-interference ability and can be used in complex scenes.

3. Communication Control Mode of Servo Motor

CAN, EtherCAT, Modbus and Profibus are common communication ways to undertake the work of communication control of servo motor. Using communication mode to control the motor is the preferred control mode in some complex and large system application scenarios. In this way, the size of the system and the number of motor shaft are easy to cut, and no complex control wiring. The system has high flexibility.

4. Other Modes of Servo Motor Control

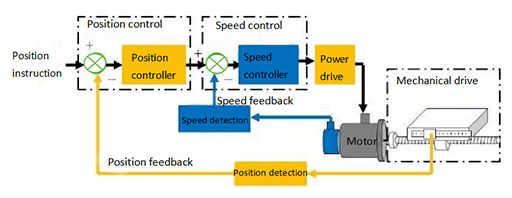

Figure 4: Work principle of position and speed control in system.

* Torque Control of Servo Motor

Torque control is to set the external output torque of the motor shaft through the input of external analog quantity or direct address assignment. Specifically, for example, if 10V corresponds to 5Nm, the output of the motor shaft is 2.5nm when the external analog quantity is set to 5V. If the motor shaft load is less than 2.5nm, the motor is rotating, and if the external load is equal to 2.5nm, the motor is not rotating. When it is greater than 2.5nm, the motor is inverted (usually in the case of gravity load). The torque can be changed by changing the setting of the analog quantity immediately or the value of the corresponding address by means of communication.

* Position Control of Servo Motor

In the position control mode, the rotation speed is generally determined by the frequency of the external input pulse, and the rotation angle is determined by the number of pulses. In addition, some servos can assign the speed and displacement directly through communication. Because the position mode can have a very strict control of the speed and position, it is generally used in positioning devices, CNC machine tools, printing machinery and so on.

* Speed Control of Servo Motor

Rotation speed can be controlled by the input of analog quantity or pulse frequency. Speed mode can also locate when the outer loop PID control of the upper control device is used, but the position signal of the motor or the direct load must be fed back to the upper computer for calculation. In this case, the encoder at the motor shaft end only detects the motor speed, and the position signal is provided by the direct detection device at the final load end. This has the advantage of reducing the error in the intermediate transmission process and increasing the positioning accuracy of the whole system.

5. Tips for Choosing Control Mode

5.1 Different Control Modes Corresponding to Speed, Position and Torque

The speed of servo motor is controlled by analog quantity.

Torque of servo motor is controlled by analog quantity.

Position of servo motor is controlled by by pulses.

5.2 Choose Control Mode According to Needs

The specific control mode should be selected according to the requirements of customers and movement function request. If you have no requirements for the speed and position of the motor, as long as the output of a constant torque, it is better to use the torque mode.

If the position and speed have a certain precision requirements, but the real-time torque is not very concerned, using the torque mode is not convenient. Insteadly, using the speed or position mode is better. If the upper controller has a better closed-loop control function, the speed control effect will be better. If the requirement itself is not very high, or no real-time requirements, the position control mode does not have very high requirements for the upper controller.

Related Info

TECO Servo JSDEP Works for Food Placement MachineBasics of Servo Motor You Should Know

Where is Servo Motor and Servo Drive Used?

Application of Servo System in Textile Machinery

Case Studies of TECO Servo Drive and Servo Motor

Why Does Servo Motor Vibrate?