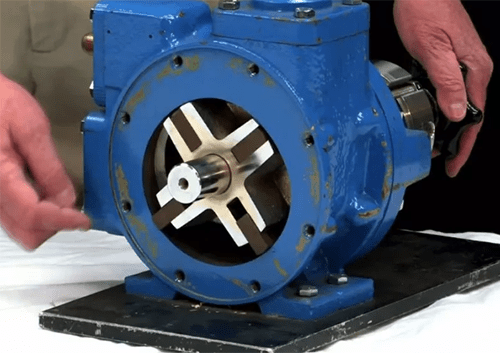

Figure 1: Blackmer sliding vane pump.

Sliding vane pump is also called vane pump, rotary vane pump, mainly composed of a rotor, a stator (i.e. pump body), vanes and cover plates on both sides. It is a kind of positive displacement pump and relies on the change of the working volume formed between the pump cylinder and the adjacent two vanes on the rotor when the eccentric rotor rotates to transport liquid or pressurize it.

1. Structure and Working Principle of Sliding Vane Pump

The sliding vane pump unit consists of a base, a electric motor, a transmission mechanism and a sliding vane pump.

The rotor of the sliding vane pump is a cylinder with radial slots and is eccentrically placed in the pump body. The sliding vanes are placed in the slots and can slide freely. When the rotor is driven to rotate by the prime mover, the sliding vane is pressed against the inner wall of the pump body by centrifugal force or spring force. The suction and discharge ports are separated by a small clearance between the rotor and the casing.

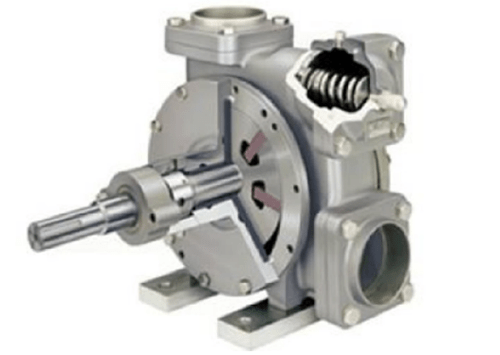

Figure 2: Rotor of sliding vane pump.

During the first half rotation of the rotor, the space enclosed by the two adjacent vanes gradually increases to form a partial vacuum to suck in the liquid. In the second half rotation, this space gradually decreases, squeezing and pushing the liquid into the discharge pipe. When the rotor rotates once, the sliding vane reciprocates in the slot once, and the vane pump completes a suction and discharge process.

If the sliding vane pump is made into a structure with variable eccentricity, the flow rate can be adjusted. If made into a structure with suction and discharge twice one revolution, it is called a double-acting sliding vane pump.

Figure 3: Sliding vane pump working principle.

2. Sliding Vane Pump Features

1. Strong self-priming ability. When used for sucking underground tanks, the lifting height can reach 5m.

2. High efficiency. The sliding vane in the pump is subject to the combined action of centrifugal force, mechanical thrust and pressure, and moves closely to the curve inside the stator, so that the pump has a unique high efficiency.

3. Self-adjusting sliding vane with constant performance. The vanes slide out of the rotor slots, constantly replenishing wear without degrading pump performance. This is essentially different from gear pumps.

4. Able to transport shear sensitive liquids. The high-efficiency design of the hydraulic sliding vane reduces the shearing force and agitation of the fluid caused by the vane when the pump rotates, and avoids the change of the fluid properties.

5. Reliable sealing. According to the characteristics of viscous and high temperature medium, the mechanical seal of sliding vane pump adopts special structure, which is safe, durable and reliable.

6. Simple and convenient maintenance. When the sliding vane is severely worn, just open the pump cover, lift out the old sliding vane, and insert a new one. It only takes a few minutes to get the pump back to work. Daily inspections are just as easy.

7. Safe and sensitive pressure guarantee. A safety relief valve is set in the pump. When the outlet system is suddenly closed, the outlet pressure rise does not exceed 0.15Mpa. This ensures the safety of the pump and the system, and on the other hand, ensures that the motor is not overloaded.

Figure 4: Sliding vane pump.

Self-priming rotary vane pump, with built-in relief valve, uses a rotor with vanes to drive the liquid. Because of its excellent performance, it can transmit viscous and volatile liquids. Compared with the equivalent pump, its power is lower, and it is more advantageous in the transmission of low speed and large flow.

3. Applications of Sliding Vane Pump

The sliding vane pump is compact in structure, small in size, uniform in flow, stable in operation, low in pulsation and noise, and has higher efficiency than general gear pumps. However, the structure and process of the sliding vane pump are complex, the manufacturing precision is high, and the parts are easy to wear.

The sliding vane pump can be used for the transportation of lubricating oil, aviation fuel, gasoline, diesel, biofuel, solvent, etc. It can be installed on any tanker truck and used on any high flow refueling machine or mobile refueling equipment.

Sliding vane pumps are also used in hydraulic systems and lubrication systems of machine tools, hydraulic presses, lifting and transportation equipment, construction machinery and plastic injection molding machines, etc.

Figure 5: Sliding vane pump in silvery.

4. Common Malfunctions of Sliding Vane Pump

4.1 No Differential Pressure

(1) The rotational direction of the rotary vane pump may be incorrect, check the direction.

(2) Maybe the medium is dirty to cause the vanes to be stuck. Toggle the drive shaft, and let it rotate forward and reverse several times to move the vanes in the pump, and if the pressure still does not go up, dismantle the pump for inspection.

(3) If there is air leakage from the suction pipe, check for and eliminate air leakage.

(4) If the fluid from the suction pipe cannot be discharged from the outlet, check each valve, open the outlet pipeline, and let the fluid discharge from the outlet.

4.2 Unable to Reach Work Pressure

(1) If the speed is too low, appropriately increase the speed.

(2) If the seal leaks a lot, first check whether the bearing is damaged. If it is not damaged, check the oil seal and replace it.

(3) If the opening pressure of the safety valve is too low, adjust the safety valve bolt to the required pressure.

(4) Maybe the internal loss of the oil pump is too large, and the main parts of the sliding vane pump, such as the eccentric sleeve of the pump body, the end cover, the rotor, the vane, etc., are worn too much, so please replace these parts.

4.3 Vibration and Noise

(1) If the bearing is damaged, replace it.

(2) Maybe the pump shaft is not concentric with the drive shaft, and the offset is too large. Adjust the concentricity between the pump shaft and the drive shaft so that the inclination angle should not be greater than 7 degrees.

(3) If the anchor bolts of the sliding vane pump are loose, tighten these bolts of the oil pump.

Related Info

What is a Hydraulic Vane Pump?How to Choose a Gear Pump?

Piston Pump: Working Principle, Types, and Features

What are Hydraulic Piston Pumps?

What is the Difference Between Piston and Plunger Pumps