Figure 1: Permanent magnet synchronous motor.

Synchronous motors like induction motors (i.e. asynchronous motors), are a common type of AC motor. The rotor speed of the synchronous motor is always equal to the speed of the armature rotating magnetic field, that is, there is a strictly invariable relationship between the rotor speed and the frequency of the armature current.

Synchronous motor is the heart of the power system. It is a component that integrates rotation and stationary, electromagnetic change and mechanical movement, and realizes the transformation of electrical energy and mechanical energy. Its dynamic performance is very complex, and has a great influence on the dynamic performance of the full power system.

1. How Does a Synchronous Motor Work

When the synchronous motor is working, the three-phase symmetrical current is connected to the three-phase windings of the stator, and DC current is connected to the excitation windings of the rotor. When a three-phase alternating current is passed into the three-phase symmetrical winding of the stator, a rotating magnetic field will be generated in the air gap. When a DC current is passed through the rotor field winding, a static magnetic field with constant polarity will be generated.

If the number of pole pairs of the rotor magnetic field is equal to that of the stator magnetic field, the rotor magnetic field will rotate synchronously with the stator rotating magnetic field due to the magnetic pull of the stator magnetic field, that is, the rotor rotates at the same speed and direction as the rotating magnetic field. This is the basic working principle of synchronous motor.

The stator and rotor magnetic fields of a synchronous motor always keep the same pace, that is, the rotation speed of the motor is consistent with the magnetic field speed. For asynchronous motors, slip is a necessary condition for motor operation, that is, the rotor speed is always less than the speed of the rotating magnetic field.

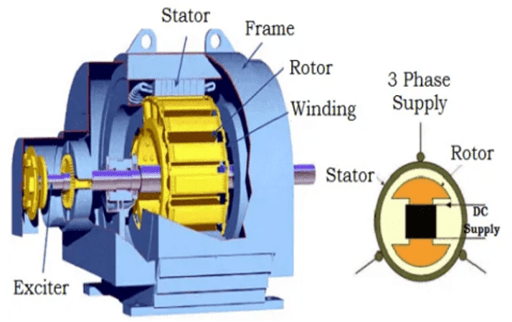

Figure 2: Structure of a DC excitation synchronous motor.

2. Features of Synchronous Motors

2.1 Constant Motor Speed

During steady-state operation, there is a constant relationship between the rotor speed of the synchronous motor and the grid frequency, n=ns=60f/p, where f is the grid frequency, p is the number of pole pairs of the motor, and ns is called the synchronous speed. If the frequency of the grid does not change, the rotational speed of the synchronous motor is constant in steady state regardless of the size of the load.

Since the synchronous motor can run under the advanced power factor by adjusting the excitation current, it is beneficial to improve the power factor of the power grid. Therefore, large equipment, such as large blowers, water pumps, ball mills, compressors, rolling mills, etc., are commonly driven by synchronous motors. This advantage is particularly prominent when synchronous motors are used in large equipment with low speed.

In addition, the rotational speed of a synchronous motor is completely determined by the mains frequency. When the frequency is constant, the speed of the motor is also constant, and it does not change with the load. This feature is of great significance in some transmission systems, especially multi-machine synchronous transmission systems and precision speed regulation and speed stabilization systems.

2.2 Stable Operation

The operating stability of the synchronous motor is also relatively high. Synchronous motors generally run in an overexcited state, and their overload capacity is greater than that of the corresponding asynchronous motors. The torque of an asynchronous motor is proportional to the square of the voltage, while the torque of a synchronous motor is determined by the product of the voltage and the internal electromotive force generated by the excitation current of the motor, that is, only proportional to the first power of the voltage.

When the grid voltage suddenly drops to about 80% of the rated value, the torque of the asynchronous motor often drops to about 64%, and stops running because it can't carry the load; while the torque of the synchronous motor does not drop much, and it can still ensure the stable operation of the motor by forcing the excitation.

3. Types of Synchronous Motors

Figure 3: Types of synchronous motor.

According to different excitation methods, synchronous motors can be divided into DC excitation synchronous motors (DC-excited motors) and non-excitation synchronous motors (non-excited motors). Non-excited synchronous motors include permanent magnet synchronous motors, hysteresis synchronous motors, and reluctance synchronous motors.

According to the operation mode, the synchronous motor is divided into generator, electric motor and synchronous condenser.

According to the structure type, synchronous motors are divided into revolving armature type and rotating magnetic pole type (revolving field type). According to the shape of the magnetic pole, the rotating magnetic pole type synchronous motor is divided into two types: cylindrical pole type (non-salient pole) and salient pole type.

According to the type of prime mover, synchronous motors are divided into steam turbine generators, hydraulic generators and diesel generators. Turbo generators are generally made of cylindrical pole type. Modern turbo generators are all 2 poles, and the speed is 3000 rpm. Hydraulic generators adopt salient pole type, with more poles and lower speed. Synchronous motors, diesel generators and synchronous condensers are generally made of salient pole type.

According to the cooling medium and cooling method, there are air cooling, hydrogen cooling, and water cooling type.

Figure 4: Types of revolving field synchronous motor.

4. Operation Modes of Synchronous Motors

Generally, there are three operating modes of synchronous motors, namely:

Synchronous generator: When converting mechanical energy into electrical energy, it is a generator mode;

Synchronous motor: When converting electrical energy into mechanical energy, it is a motor mode;

Synchronous condenser: when no power is absorbed or output on the shaft, i.e., no-load operation, it is the synchronous condenser mode.

4.1 Generator Mode

Operating as a generator is the most dominant operation mode of synchronous motor.

4.2 Electric Motor Mode

Running as a motor is another important operation mode of a synchronous motor. The power factor of the synchronous motor can be adjusted. In the occasions where speed regulation is not required, the application of a large synchronous motor can improve the operating efficiency. Small synchronous motors are beginning to be used more often in variable frequency speed control systems.

4.3 Synchronous Condenser Mode

The synchronous motor can also be connected to the grid as a synchronous compensation machine. At this time, the motor does not carry any mechanical load, and sends the required inductive or capacitive reactive power to the grid by adjusting the excitation current in the rotor to achieve the purpose of improving the power factor of the grid or adjusting the grid voltage.

Figure 5: Structure of permanent magnet synchronous motor.

5. Applications of Synchronous Motors

Since the synchronous motor can only run at the synchronous speed, the synchronous motor cannot start automatically when it is used as a motor. For this reason, synchronous motors must be equipped with special asynchronous starting windings. Compared with asynchronous motors, synchronous motors are more complex in structure and more expensive, but synchronous motors have a higher power factor.

Therefore, high-power units that do not require speed regulation are often driven by synchronous motors, such as rolling mills, blowers, turbo compressors, and large ship propulsion.

Synchronous motors can be used as synchronous condenser. A synchronous condenser is essentially a synchronous motor with no mechanical load on the shaft. By adjusting the excitation current of the synchronous motor, it can control the phase of the reactive current absorbed from the grid, so as to achieve the purpose of adjusting the power factor of the power grid and maintaining the voltage level of the power grid.

Related Info

What is Three Phase Induction Motor and How Does It WorkSquirrel Cage Induction Motor Vs Wound Rotor Induction Motor: Rotor Structure, Pros and Cons

FANUC Spindle Amplifier Alarm Codes and Solutions (3)

FANUC Spindle Amplifier Alarm Codes and Solutions (4)