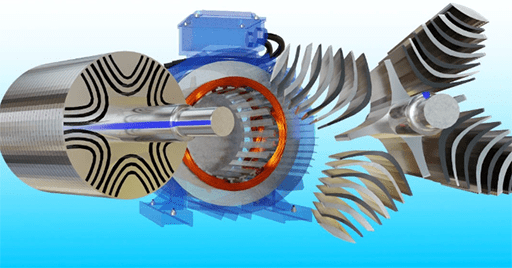

Figure 1: Danfoss synchronous reluctance motor.

Permanent magnet synchronous motors have received extensive attention in the motor industry due to their compact structure, high energy density and high efficiency. However, the existing high-performance rare earth permanent magnet materials are expensive and the price fluctuates greatly. Now both domestic and foreign companies are looking for products that can replace permanent magnet synchronous motors.

All manufacturers hope that the permanent magnet ferrite with slightly lower performance can be used or even remove the permanent magnet, while the motor can still maintain good performance. Synchronous reluctance motor (SynRM) thus comes into the limelight.

In fact, the concept of synchronous reluctance motor has been proposed as early as the 1920s, that is, the difference between the d-axis and the q-axis reluctance generates torque to drive the motor. In recent years, the demand for low-cost and high-performance motors has risen sharply in industrial development. With the advancement of electronic devices and field-oriented control technology, synchronous reluctance motors have been applied in quite a few applications.

1. Comparison of Synchronous Reluctance Motor and Other Motors

1.1 Synchronous Reluctance Motor vs Asynchronous Motor

In terms of processing technology and materials, the rotor core of the synchronous reluctance motor only needs to be stamped and laminated, which is more advantageous than an asynchronous motor which requires subsequent processes after stamping and laminating.

Regardless of the complexity of the process, the output torque of the asynchronous motor will be higher than that of the synchronous reluctance motor under the same stator winding current density; but considering the core wear, the efficiency of the synchronous reluctance motor will still be slightly higher under the same wear of the two motors.

Synchronous reluctance motors are basically used in the field of variable frequency speed regulation, while asynchronous motors can be used for self-starting operation and variable frequency speed control operation. Although the synchronous reluctance motor can be designed in a self-starting mode, it is very expensive to complete this mode at the expense of the salient pole rate.

On the whole, the main advantage of synchronous reluctance motor compared with asynchronous motor is the low rotor losses, while the shortcomings are the lack of self-starting and low power factor.

Figure 2: Synchronous reluctance motor.

1.2 Synchronous Reluctance Motor vs Permanent Magnet Synchronous Motor

As the most commonly compared model with synchronous reluctance motors, permanent magnet synchronous motors are definitely not as advantageous as synchronous reluctance motors in terms of cost and processing technology. It can be said that the cost of synchronous reluctance motors is much lower than that of any type of permanent magnet synchronous motor.

The torque density, efficiency and power factor brought by the high cost and complex processing technology of the permanent magnet synchronous motor, are undisputedly ahead of the synchronous reluctance motor. In particular, the efficiency and power factor are significantly ahead. Only in terms of torque density, the synchronous reluctance motor will be closer to the ferrite permanent magnet motor.

In terms of mechanical properties, since the rotor of the synchronous reluctance motor generally adopts a multi-layer magnetic barrier, it will be weaker than the permanent magnet synchronous motor with only one layer of magnetic barrier.

As a product to replace the permanent magnet synchronous motor in the case of cost-sensitive, it is normal that the synchronous reluctance motor is weaker than the permanent magnet synchronous motor in terms of performance indicators. With the in-depth breakthrough of synchronous reluctance motor technology in the industry, the performance index of it will be closer and closer to that of the permanent magnet synchronous motor.

Figure 3: Structure diagram of permanent magnet synchronous motor.

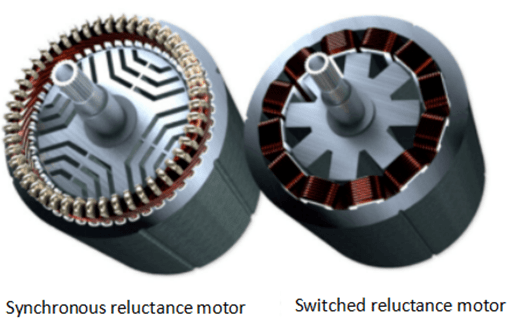

1.3 Synchronous Reluctance Motor vs Switched Reluctance Motor

From the processing technology, the rotor of the switched reluctance motor is usually designed with geometric salient poles, which is obviously simpler than the rotor process of the synchronous reluctance motor with multi-layer magnetic barriers. The synchronous reluctance motor has multi-layer magnetic barriers, and each layer is connected by a thin magnetic bridge, whose rotor will not be as robust and reliable as that of the switched reluctance motor. However, the salient pole structure still has an unavoidable point, that is, the air friction loss of the rotor will be significantly larger during operation.

On the drive, the synchronous reluctance motor needs the sinusoidal current formed by the PWM chopped wave to control, so the control difficulty will definitely be higher, and the cost of the driver will be higher. Sophisticated control brings less torque ripple, less vibration, lower noise and higher efficiency under rated operating conditions.

Figure 4: Structure of synchronous reluctance motor and switched reluctance motor.

2. Summary of the Advantages of Synchronous Reluctance Motors

2.1 Better

Synchronous reluctance motors are more efficient than asynchronous motors and can achieve energy efficiency above IE4. The 25%~120% load range is the high-efficiency area. By replacing asynchronous motors with synchronous reluctance motors of the same power, the energy efficiency of the system is greatly improved, and the comprehensive power saving effect is as high as 30%.

2.2 Smaller

Compact and customizable. Synchronous reluctance motors use IEC standard casings (cast aluminum or cast iron casings can be used as required). The installation dimensions refer to the IEC standard frame. The synchronous reluctance motor is more than 25% smaller than the asynchronous motor of the same power. It can be customized according to customer needs, suitable for a variety of installation methods, and compatible with a variety of external device interface designs.

2.3 Stronger

Constant and durable. There is no risk of demagnetization of the rotor, and the loss is small. The low bearing temperature ensures long-term stability of the bearing lubrication system. The motor operation has small rotor loss, and the temperature rise margin is large. In the range of 10%-100% rated speed, the motor can maintain constant torque operation, and allow 1.2 times of long-term overload operation, and can withstand 3 times of overload in an instant, which is also applicable in self ventilated motors.

Figure 5: Synchronous reluctance motor.

2.4 Faster

Starting quickly. Squirrel cage bars and magnetic steel are eliminated on the rotor, and large-area magnetic barrier slots are used for rotor punching, so that the rotational inertia of the synchronous reluctance motor rotor is small. Under the same specifications, the rotational inertia of the synchronous reluctance motor is 30% of that of the asynchronous motor. Synchronous reluctance motors can be applied to occasions with high requirements on acceleration response capability, and significantly reduce the peak current of the motor.

2.5 Wider

Widely applicable. The rotor of the motor is light in weight, non-magnetic, easy to disassemble and assemble, and safe to maintain. After disassembly, no special protective treatment is required, and it can easily cope with harsh environments without fear of extreme operating temperatures.

2.6 Other Advantages

1. The motor utilization rate of the synchronous reluctance motor is very large, which can be 1.2~1.4 times that of the induction motor.

2. The motor has a simple structure, and there is no winding in any form on the rotor; there is only a simple concentrated winding on the stator, with shorter ends and no interphase jumpers. Therefore, it has the characteristics of less manufacturing process, low cost, reliable operation and less maintenance.

3. The torque of the synchronous reluctance motor has nothing to do with the current polarity, only requiring unidirectional current excitation.

4. The structure of the synchronous reluctance motor rotor has a small speed limit and it can be made into a high-speed motor.

Related Info

What is Three Phase Induction Motor and How Does It WorkWhat is Synchronous Motor

Squirrel Cage Induction Motor Vs Wound Rotor Induction Motor: Rotor Structure, Pros and Cons

What is the Difference between Synchronous and Induction Motor

What is Synchronous Reluctance Motor and How Does It Work