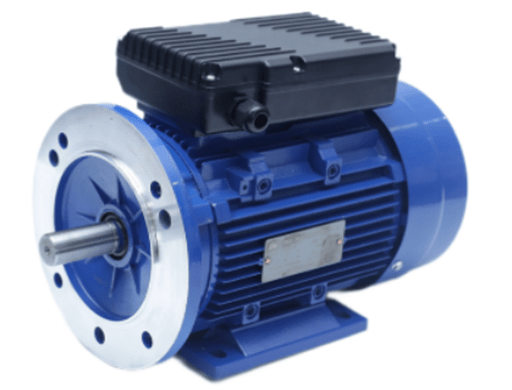

Figure 1: Asynchronous motor.

Electric motors are roughly divided into three types, synchronous motor, asynchronous motor (induction motor), and DC motor. The following article describes some of the differences between synchronous motors and induction motors and compares their advantages and disadvantages respectively.

1. Induction Motor

The asynchronous motor is connected to the three-phase AC power supply from the stator side, and the three-phase symmetrical current flowing through the stator winding generates three-phase magnetomotive force (stator rotating magnetomotive force) and a rotating magnetic field. The rotating magnetic field has a relative cutting motion with the rotor conductor.

According to the principle of electromagnetic induction, the rotor conductor generates an induced electromotive force and an induced current. According to the law of electromagnetic force, the current-carrying rotor conductor is subjected to electromagnetic force in the magnetic field to form electromagnetic torque, which drives the rotor to rotate.

The speed of the asynchronous motor is less than the speed of the rotating magnetic field of the stator, and there is a slip, so it is called an asynchronous motor. Because the rotor winding current is generated by induction, it is also called induction motor.

The synchronous speed of the asynchronous motor, that is, the speed of the rotating magnetic field is: n=60f/p, where:

n——the synchronous speed of the asynchronous motor;

f——power frequency;

p——number of pole pairs.

It can be seen from the above formula that changing the supply frequency of the asynchronous motor can change its synchronous speed, so as to realize the speed regulation operation, that is, the frequency conversion speed regulation.

Figure 2: Construction of Induction Motor.

2. Synchronous Motor

The stator side of the synchronous motor is fed with three-phase alternating current, and the rotor side is fed with a direct current at the same time to generate a magnetic field with a constant direction relative to the stator. This magnetic field rotates at the same speed as the rotating magnetic field generated by the stator, so it is called a synchronous motor.

The rotor speed n, the synchronous speed ns, the number of pole pairs p and the power frequency f satisfy n=ns=60f/p. The rotation speed n is determined by the power frequency f, so when the power supply frequency is constant, the rotation speed does not change, and has nothing to do with the load. It has the characteristics of high running stability and large overload capacity.

In the past electric traction, synchronous motors were rarely used, and they were mainly used as generators. The main reason was that synchronous motors could not start by themselves under the grid voltage. Under the action of the rotating magnetic field, the average torque of the stationary rotor poles was zero. However, in recent years, with the development of power electronic technology, the problem of starting and speed regulation of synchronous motor has been solved, and the synchronous motor has appeared as a prime mover in electric traction.

3. Synchronous Motor Vs Induction Motor

3.1 Motor Design

The biggest difference between synchronous motors and induction motors is whether their rotor speed is consistent with the stator rotating magnetic field. The rotor speed of the synchronous motor is the same as the stator rotating magnetic field, while the speed of the asynchronous motor is lower than the electromagnetic speed.

Regardless of load size, the speed of the synchronous motor will not change as long as it does not lose steps. The speed of the synchronous motor is only related to the frequency of the stator power supply. The speed of the asynchronous motor is only related to the load (of course there is a certain range), and it follows the change of the load size at all times.

In addition, the stator windings of the synchronous motor and the induction motor are the same, the difference lies in the rotor structure of the motor. The rotor of the asynchronous motor is composed of steel sheets and aluminum bars (or steel sheets and coils), while synchronous motors are generally composed of several magnets and coils.

The rotor of an asynchronous motor is a short-circuited winding that generates current by electromagnetic induction. The rotor structure of the synchronous motor is relatively complex, and there are DC excitation windings, so an external excitation power supply is required to introduce current through the slip ring. There are also synchronous motors that do not require excitation, such as permanent magnet synchronous motors.

Figure 3: Structure of Permanent magnet synchronous motor.

3.2 Reactive Power

Active power is the power consumed by the equipment and converted into other energy, while reactive power is the energy that keeps the equipment running but is not consumed. Reactive power exists between the power grid and equipment, and is an indispensable energy part of them. However, if too much reactive power is occupied by equipment, it will cause problems such as low power grid efficiency.

Compared with induction motors, which can only absorb reactive power, synchronous motors can emit or absorb reactive power! The synchronous motor itself has a complete excitation circuit to establish a magnetic field, which can autonomously control the excitation current and emit or absorb reactive power. The asynchronous motor itself has no excitation circuit, and needs the system to provide reactive power to establish a magnetic field, so it needs to absorb reactive power.

3.3 Power Supply

In terms of power supply, the induction motor only applies voltage to the stator side (there is also voltage applied to the rotor side), while the synchronous motor needs to apply voltage to both the stator and the rotor. The permanent magnet synchronous motor rotor is excited by permanent magnets, no need to be energized and excited separately, so the rotor does not need to add voltage. That is to say, the asynchronous machine is unilaterally excited, and the synchronous machine is bilaterally excited.

Figure 4: Excitation of synchronous motor.

3.4 Application

Synchronous motor has high precision, but complex construction, high cost and relatively difficult to maintain, while asynchronous motor is slow to respond, but easy to install and use, and cheap at the same time. Therefore, synchronous motors are not as widely used as asynchronous motors. Synchronous motors are mostly used in large generators, while asynchronous motors are almost used in electric motors.

The synchronous motor can flexibly adjust the voltage and current phases on the input side through excitation, that is, the power factor. When users’ electrical equipment at a certain voltage and power, the higher the value, the better the benefit, and the more fully the power generation equipment can be utilized.

The power factor of the asynchronous motor is not adjustable, generally between 0.75-0.85. Therefore, in some large factories, when there are many applications of asynchronous motors, an additional synchronous motor can be used as a synchronous condenser to adjust the power factor at the interface between the factory and the power grid. However, due to the high cost and heavy maintenance workload of synchronous motors, capacitors are generally used to compensate power factor.

Figure 5: All kinds of synchronous motors.

4. Comparison of Advantages and Disadvantages

4.1 Advantages of synchronous motors

1.The power factor of the synchronous motor is high and can be adjusted. In the occasions where speed regulation is not required, the application of a large synchronous motor can improve the operating efficiency.

2.High operating efficiency: Relying on the applied scientific working principle and relatively advanced product technology, the synchronous motor has the advantage of high operating efficiency, so that the motor can function efficiently and fully optimize the operation of the equipment.

4.2 Disadvantages of synchronous motors

The cost is relatively high compared to asynchronous motors.

4.3 Advantages of asynchronous motors

It has a series of advantages such as simple structure, easy manufacture, low price, reliable operation, convenient maintenance, and durability. Asynchronous motors have high operating efficiency and good working characteristics, and operate at a nearly constant speed from no-load to full-load, which can meet the transmission requirements of most industrial and agricultural production machinery.

4.4 Disadvantages of asynchronous motors

Since the speed of the asynchronous motor has a certain slip relationship with the speed of its rotating magnetic field, its speed regulation performance is poor (except for the AC commutator motor). Compared with the synchronous motor, its power factor is not high, and it must absorb the lagging reactive power from the grid during operation, which is not good for the grid operation. However, with the continuous advancement of science and technology, the development of asynchronous motor speed regulation technology is rapid, and other methods can also be used to compensate for the power factor of the power grid.

5. Summary

Synchronous motors and asynchronous motors have their own advantages and disadvantages. It is difficult to evaluate which one is good and which one is not good. It depends on the specific needs. If you want a high-precision motor, it is recommended to use a synchronous motor; if you want to facilitate installation and operation, it is recommended to use an asynchronous motor. It is necessary to use synchronous or asynchronous motors according to different use environments and needs.

Related Info

What is Three Phase Induction Motor and How Does It WorkWhat is Synchronous Motor

Squirrel Cage Induction Motor Vs Wound Rotor Induction Motor: Rotor Structure, Pros and Cons

FANUC Spindle Amplifier Alarm Codes and Solutions (3)

FANUC Spindle Amplifier Alarm Codes and Solutions (4)