Application of synthetic compressor oil

Application of synthetic compressor oil

At present, synthetic lubricants are widely used in the compressor field. Among them, oil-injected and oil-immersed rotary screw air compressors and large reciprocating compressors are one of the most used markets. For example, the sales volume of synthetic compressor oil in Western Europe was 6000t in the late 1980s, and it rose to 10000 in the early 1990s. The sales volume in the United States has exceeded 15,000 tons, and it is increasing at a rate of more than 10% per year.

The following types of compressors are currently using or expanding the use of synthetic compressor oil:

2. Types and characteristics of synthetic compressor oil:

The synthetic oils currently used as compressor oils include esters (diester, neopentyl polyol ester), synthetic hydrocarbons, polyethers and silicone oils. The type of synthetic oil can be selected according to the compressor structure, compression medium, technical parameters and working conditions. In addition to the common characteristics, the above-mentioned synthetic oils also have different characteristics.

The use temperature limit of synthetic oil

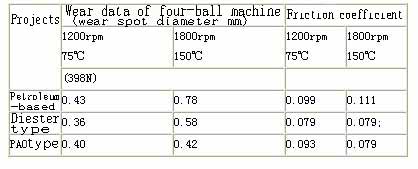

Comparison of lubrication performance of different types of compressor oil

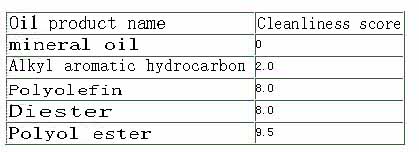

Comparison of biological degradation of synthetic oil and mineral oil (CEC-L33-T-82 method)

1. Ester oil

The esters used as synthetic compressor oil mainly include neopentyl polyol ester and diester. Ester oil meets the lubrication requirements of most screw and reciprocating air compressors with its unique excellent comprehensive performance.

The outstanding advantages of ester oil are:

Good high and low temperature performance, thermal oxidation stability, flash point and natural point are about 40℃ higher than mineral oil, and the use temperature is 50℃ higher than mineral oil.

Very low volatility, low fuel consumption, only 1/8 of mineral oil consumption.

Low residual carbon, good melting, maintain the high-definition clarity of the lubrication system, coupled with high flash point and high natural, greatly improve the safety of equipment operation and avoid safety accidents.

Ester oil has polarity and high strength of the oil film formed on the metal surface, so it has low friction coefficient and good lubricating performance.

Ester oil has a high thermal conductivity, its thermal conductivity is 15% higher than that of mineral oil, and its specific heat is larger, and its heat capacity is 5∽10% larger than mineral oil. Therefore, the heat dissipation is good, which can effectively reduce the temperature of the oil tank and the lubrication system.

Ester oil has extremely low toxicity and biodegradability, especially the biodegradability of diester and polyester used in compressor oil can reach more than 90%, which can reduce environmental pollution.

Many lubrication problems solved by synthetic oils are related to temperature, in order to prevent water and other refrigerants that exceed the heat resistance of general mineral oils from condensing in the compressor system. Therefore, it is advantageous to require the compressor to work at high temperatures. Due to the gel effect of mineral oil containing wax and the poor low-temperature performance of parts and low viscosity index, it is difficult to start the compressor in the field and under low-temperature conditions. The good high and low temperature performance, viscosity-temperature performance, and wide temperature range of synthetic oil solve the above problems. Synthetic oil has a higher viscosity at high temperatures, and the compressor is easy to start at low temperatures. The synthetic oil with higher viscosity during operation ensures that the screw compressor has a high volumetric efficiency.

Synthetic ester compressor oil is more suitable for multi-stage high pressure screw air compressors with continuous heavy load and operating temperature higher than 93℃. The service life can be doubled than PAO type oil. Another main feature of synthetic ester oil is its low carbon residue. It inhibits the generation of sludge, precipitation and coke during use, improves the cleanliness of the crankcase and oil, makes heat transfer good, reduces friction and resistance to moving parts, thereby reducing Maintenance and downtime can reduce power consumption costs by 7.2% and save power by 3%. While synthetic ester is used in reciprocating air compressors, its high flash point and good oxidation stability show its superiority. For the lubrication of single-pass cylinders of large reciprocating air compressors, common problems are in the cylinder and exhaust valve. Carbon residue and oily sludge are formed in the system, causing frequent maintenance and shutdown. What is more serious is that when the original mineral oil is used, the compression system will automatically catch fire when the temperature is lower than 149 ℃ due to the excessive carbon residue and rust lubricant and high pressure. It even caused an explosion. Due to the application of diester compressor oil, considerable economic benefits have been achieved. For example, a foreign company used three years to test 100 rotary vane and screw compressors, and to track and monitor the tested double ester compressor oil and compressors. All the tested compressors exceeded the expected oil change. time. The oil change period of rotary vane compressors has been extended from 500 hours using mineral oil to more than 4,000 hours, and several tests lasted more than 10,000 hours. Rotary screw compressors have been extended from the original 1,000 hours to more than 8,000 hours, and several tests lasted more than 13,000 hours. In the same experiment with reciprocating compressor with diester oil, the cleanliness of the cylinder and crankcase was improved, and the valve cleaning cycle was prolonged by seven times.

At present, the world's major oil companies such as CPI (Sipeier), Mobil, Shell, BP, Esso, Castrol, Caltex, Ethel, Tanneco, Amoco, etc. have developed their own series of synthetic ester compressor oils. Among them, the American CPI Engineering Company is the world's largest compressor oil expert.

Typical data of diester compressor oil

2. Synthetic hydrocarbons (PAO)

Synthetic hydrocarbons here mainly refer to poly alpha olefins. Because synthetic hydrocarbon oils are superior to mineral oils in many properties, they are used more and more widely in industrial fields, including compressor oil applications.

Synthetic hydrocarbon has low pour point, good viscosity-temperature performance, high viscosity index, high flash point, low evaporation loss, low carbon residue, good high temperature and thermal oxidation stability, good adaptability to non-metal and metal materials, non-toxic, etc. Features.

The main performance characteristics of synthetic hydrocarbon oil:

It can be seen from the above data that the viscosity index of synthetic hydrocarbon oil is greater than 135, which can replace viscosity index improvers for the preparation of various lubricating oils, and has good shear resistance. The good high and low temperature performance can be used in a wide temperature range, ensuring that the mechanical equipment for oil products working in the cold area has good low temperature starting performance and pumping performance.

Synthetic hydrocarbon oil has chemical properties: good thermal stability,

Comparison of thermal stability of several oils (aluminum plate temperature 310℃, oil thermometer 121℃)

Note: 10 is clean and 0 is severe carbon deposit.

1. Good antioxidant stability:

Poly-olefin has better oxidation stability than mineral oil. If the oxygen bomb test is carried out under the same conditions, the time when the pressure drops to 172Kpa for mineral oil 100SN and 250SN is 100 minutes and 180 minutes, respectively. However, PAO 4 and 6 are 380 and 400 minutes respectively, which is twice as long as mineral oil.

2. Good hydrolysis stability:

Poly-a olefin oil has good hydrolysis resistance and stability, and is generally stable in the presence of water. 3. Good material adaptability:

Poly-a olefin oil and mineral oil have basically the same adaptability to metal and non-metal materials.

The main disadvantages of poly-a olefin:

One is that some rubbers will shrink and become hard, which will affect the sealing performance. For this reason, a rubber expansion agent must be added.

The influence of synthetic hydrocarbon oil on various rubber properties

Another disadvantage is the poor solubility of certain additives. The above two problems can be solved by adding a small amount of ester oil.

Application of synthetic hydrocarbon oil:

Due to the excellent comprehensive performance of synthetic hydrocarbons, its application range is continuously expanded. It is especially suitable for lubricating oil used in high temperature and wide temperature range, and general mineral oil for mechanical equipment in cold area, severe cold area and field operation cannot meet the requirements. At present, it has been widely used in automobile engine oil, compressor oil, hydraulic oil, gear oil, circulation system oil, etc.

Synthetic hydrocarbon (PAO) oil has good hydrolysis stability modification, excellent water separation and high temperature oxidation stability, especially suitable for seals of centrifugal air compressors whose working pressure is less than 1Mpa and working temperature is not higher than 82℃ , Gear and bearing lubrication. The service life of the compressor can be prolonged. The service life of the oil filter is prolonged due to the extension of the oil change period and the overhaul period, which reduces the downtime and improves the production efficiency. The savings that can be made far exceed the increased costs due to the use of synthetic oils.

Since synthetic hydrocarbons are non-toxic and colorless and are used in the food and pharmaceutical industries, the working life of the food-grade synthetic hydrocarbon screw air compressor oil can be reached after adding additives that comply with the US Food and Drug Administration (FDA) regulations 8000 hours.

Because synthetic hydrocarbons have good chemical stability, when the acid gases such as carbon dioxide, sulfur dioxide, hydrogen chloride, chlorination, and methane produced by chemical plants are compressed, the compressor equipment and lubricating oil are chemically corroded, and the pressure and temperature Increased by the rise. Since mineral oil has the effect of inhibiting the catalyst, it is generally prohibited to use it. Suitable lubricating oils include synthetic hydrocarbons, silicon oils, and hydrogenated and cracked saturated hydrocarbons. Since synthetic hydrocarbons are not mutually soluble with the above compressed gas, they can ensure a better volumetric efficiency in the rotary compressor, and the effect is very satisfactory.

Synthetic hydrocarbons are also widely used in refrigeration compressors. Because of the characteristics of more branched chains, they can provide a three-dimensional thick oil film and improve lubricity. It is suitable for ammonia and halogenated hydrocarbons (R-12, R-22, R-114, etc. ) Is a refrigerant compressor. The synthetic hydrocarbon is extremely stable in matching with the refrigerant. Its high viscosity index and good low temperature performance ensure that the compressor is cold-started at a very low temperature. The synthetic hydrocarbon does not contain wax, no flocculation point, and does not have the problem of blocking the expansion valve and control pipe. At the same time, synthetic hydrocarbons are also suitable for industrial heat pumps operating at high temperatures. For example, the R-114 system used for compression temperature up to 120℃ has good stability. Low-viscosity synthetic hydrocarbons are used in R-13 and R-503 refrigeration systems, and the temperature of the evaporator can be lower than -46°C. Can well meet the requirements of use.

Synthetic hydrocarbon (SHC) compressor oil typical data

3. Polyether oil (PAG)

Polyether lubricants are based on the homopolymerization of propylene oxide or the product of random copolymerization with ethylene oxide as the main basic material. Since its industrialization in the 1960s, its application range has been continuously expanded. Polyether oil has low pour point, good low-temperature fluidity, high flash point, can reach above 220 ℃, high viscosity index, generally> 200, good lubricating performance, because the polyether molecule has polarity and high bearing capacity, It can form a stable oil film under various lubrication conditions, especially for steel/bronze friction pairs. It has better corrosion resistance and unique high-temperature performance, especially the use of variable factors in polyether molecules to flexibly tune products with different viscosities To meet the requirements of various performances. The low solubility of polyether and hydrocarbon gas has made it widely used in the compressor for compressing and conveying hydrocarbon gas in chemical industry. These characteristics of polyether oil make it successfully widely used in high temperature lubricating oil, gear oil, compressor oil, flame-resistant hydraulic oil, brake fluid, metalworking fluid and special grease base oil. It is one of the largest types of synthetic lubricants currently produced.

In a large-scale high-pressure ethylene production plant, the mixed raw material gas of ethylene and vinyl acetate is transported to the reactor through an ultra-high pressure compressor. The suction pressure of this type of compressor is 26 MPa, and the outlet pressure is 300 MPa as desired. The compressor oil is in the plunger and seal. The parts play a role of lubrication and sealing, and the compressor works for a long time, and the working conditions are very harsh. When mineral oil is used, high-pressure ethylene gas will easily dilute the compressor oil, resulting in poor lubrication, pressure drop, and even wear of seals, gas leakage, and resultant production. The above problems can be solved by using polyether compressor oil.

Since the dilution of hydrocarbon gas in PAG oil is very low, the amount of oil carried in the recovered gas is very small. It is especially suitable for the recovery of hydrocarbon vapors such as hexane and butene. The oil consumption is very low and the oil change period is up to more than a year. Similarly, the extensive experience of PAG used in propane screw compressors as the refrigerant shows that the volumetric efficiency of PAG oil is 18% higher than that of mineral oil. When the pressure ratio is 2-10, the adiabatic efficiency increases by 5%-8%. PAG oil The sealing life is extended by more than 10 times.

Another feature of PAG oil is that low molecular oxidation products that are easily broken in the presence of oxygen at high temperatures (>220℃) can be dissolved in the oil or quickly evaporate, so PAG will not generate deposits and deposits when used at high temperatures. Jelly. And it has good sensitivity to additives. Adding phenol and aromatic amine high temperature antioxidants can significantly improve high temperature oxidation stability. In addition, random polyethers with phenols and amines as initiators have high thermal oxidation stability. Therefore, it is widely used in the field of lubrication. Especially in high temperature chain oil, gear oil, compressor oil, etc., the amount is large.

PAG oil is also particularly suitable for the lubrication of large screw compressors using propane as a refrigerant in petrochemical industries. (Cp-1516 series is suitable for propane refrigeration)

In recent years, in order to save energy, eliminate the torch of combustible gas in the refinery, and reduce environmental pollution, the major domestic refineries have adopted screw compressors to recover the torch gas. The recovered gas is used as the heating furnace. fuel. Since flare gas mainly contains hydrocarbon gases such as methane and ethylene, the use of polyether compressor oil is the best choice. (Cp-1515xilie and cp-1516xilie)